86514-86880517

2025-03-07 157

Committed to fully promoting the localization of high-end metal forming machine tool equipment, Yawei shares in the sheet metal machine tool business to achieve high-end import substitution, industry leading edge gradually expanded on the basis of the domestic development prospects of high-end servo press products, expand the metal forming machine tool industry in the highest proportion of the largest value of the press business, In the automobile, home appliances, new energy, 3C and other industries have formed large-scale sales, and the investment of 680 million yuan in the construction of the "servo press and automatic stamping line technology transformation project" will further promote the high-quality development of the stamping industry. Below, follow Xiaobian together, and check our comprehensive introduction to Yawei servo press!

Aerial view of the project

Yawei servo press application scenario

Progressive die stamping: using pendulum stamping mode, shorten the empty stroke time of the punch, double the production capacity, and save nearly 40%;

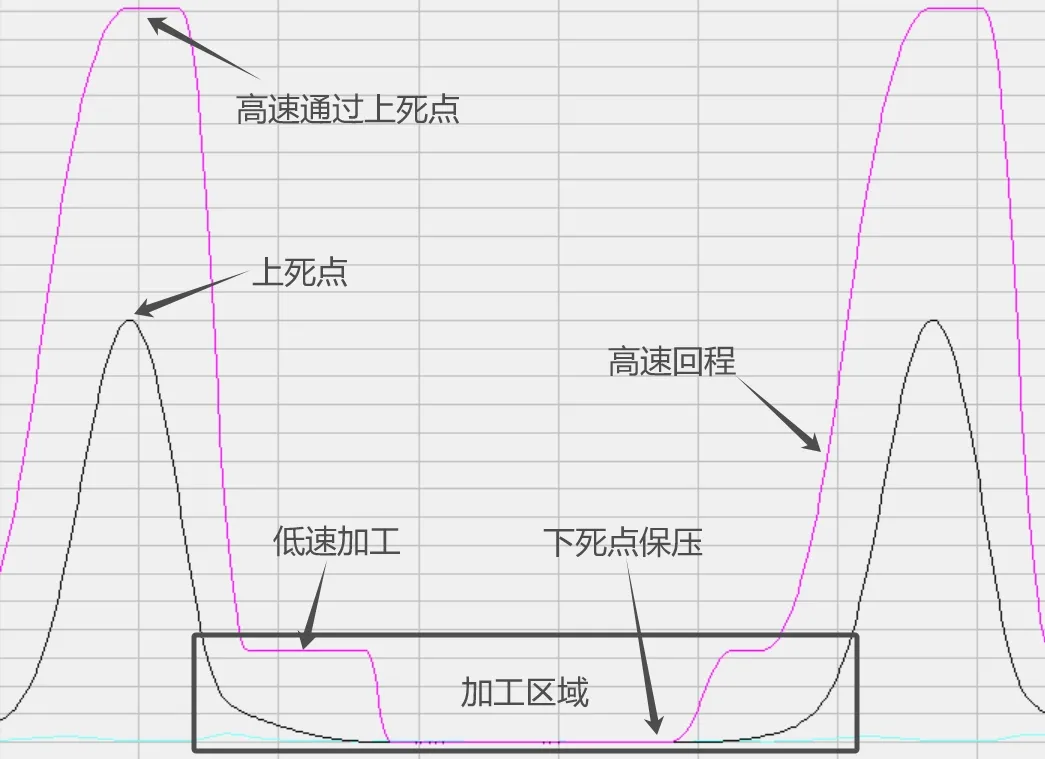

Deep drawing stamping: The drawing mode can reduce the speed of the slider drawing working area and make it tend to be uniform, which is conducive to the uniform flow of sheet metal, improve the ductility of the workpiece drawing, and improve the empty stroke speed before the mold closure and the return of the slider, shorten the empty stroke cycle, and achieve the product forming quality of the hydraulic press and the effect of high beat of the mechanical press;

Aluminum alloy stamping: The use of pressure holding stamping mode, without multi-process stamping can achieve a product forming processing;

High strength steel stamping: the use of pressure holding or pulse + pressure holding stamping mode, effectively inhibit the rebound deformation of the product;

Medium and thick plate stamping: the use of silent or multi-link stamping mode, through acceleration and deceleration changes, so that the closing speed is greatly reduced, reduce the impact of the closing, effectively inhibit the noise of thick plate processing, while improving the empty stroke speed;

Free programming stamping: The use of free programming stamping mode (can edit 20 parameter inflection points), the slider displacement, speed, stop time and other modes are arbitrarily set;

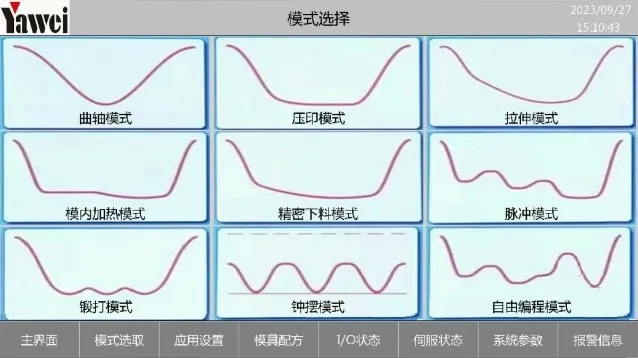

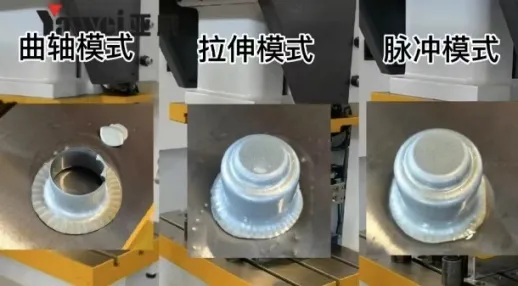

The motion curve of servo press can be planned at will, and the factory equipment has preserved mature and stable crankshaft, multi-connecting rod, pressure holding, unilateral, pendulum, silent blanking, repeated pressure and other stamping mode parameters, which are suitable for various stamping scenes, and are widely used in auto parts, home appliances, motors, kitchenware, hardware, 3C electronics and other industries.

Yawei servo press product system

Yawei currently offers open single point precision servo presses (45 tons to 315 tons optional), portal double point precision servo presses (110 tons to 630 tons optional) and closed type servo presses (500 tons to 2400 tons optional for multi-link four-point/eccentric four-point structure, 200 tons to 1600 tons optional for eccentric two-point structure).

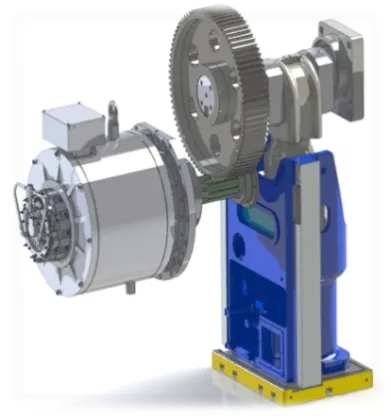

Yawei servo press adopts low speed, high torque special servo motor direct drive structure, no backlash connection, through the big gear, crankshaft, connecting rod structure to drive the slider free movement. Yawei uses the unique full closed-loop feedback control technology, the slider position is precisely controllable, which can meet the needs of various special stamping process and improve the yield and quality of stamping parts.

|  |

Yawei servo press advantages

01.High flexibility, one machine can do more

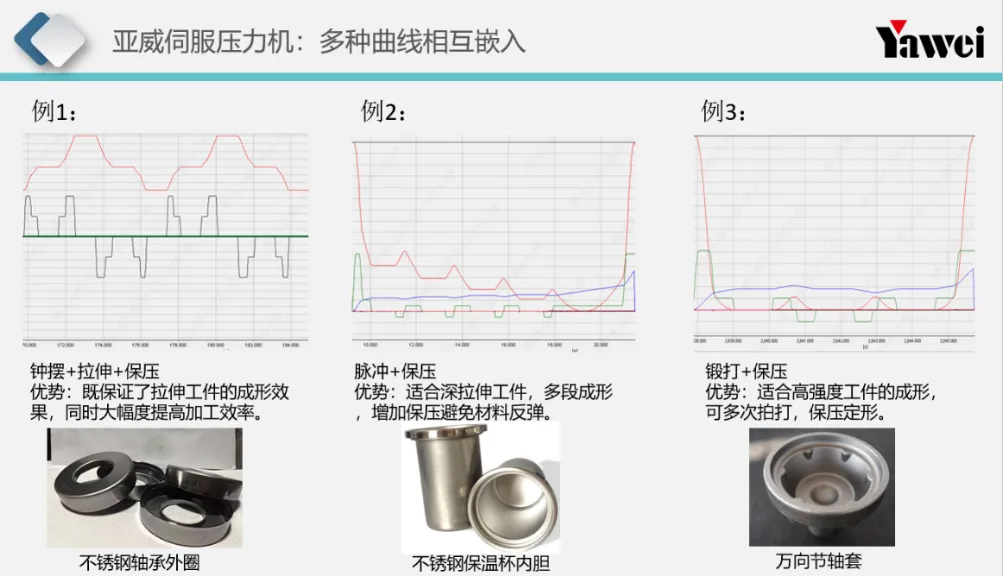

Yawei servo press control system comes with 8 standard stamping modes to meet the needs of stamping customers in various application scenarios; The operation is simple and convenient, only need to set the parameters of running spm, starting machining position and machining end position. Yawei control system can adaptively adjust the stamping running curve by simple parameter setting of customers and intelligent AI algorithm. By changing the cutting speed, blanking speed, fine blanking speed, bending speed, drawing speed, forging extrusion speed, indentation speed and so on these different speed indicators, not only can improve the accuracy and quality of the processed products, but also improve the processing efficiency, and the flexible stamping method makes the die life increased by at least 5 times more. In addition, the system is also configured with a free programming mode, which provides a shortcut for the special needs of customers or "process gods", through the free setting of the mode or the mutual embedding/compounding of various standard stamping curves, so as to meet the combination of efficiency, quality and accuracy, as shown in the following figure.

02.High precision, excellence

Yawei servo press adopts servo direct drive technology, using 21-bit absolute encoder, can accurately control the motion position, and form a closed loop measurement of the position with the "passive" detection of the crankshaft encoder, through the control system for micro-second interpolation, so as to achieve high precision of the slide operation.

If the slide magnetic grid ruler is selected, the positioning accuracy of the slide block can reach the silk level. Electrical control technology makes up for the comprehensive gap of mechanical assembly, so that the press products have evolved from pure mechanical products to numerical control products, and the accuracy and efficiency have been improved, which is more favored by young entrepreneurs.

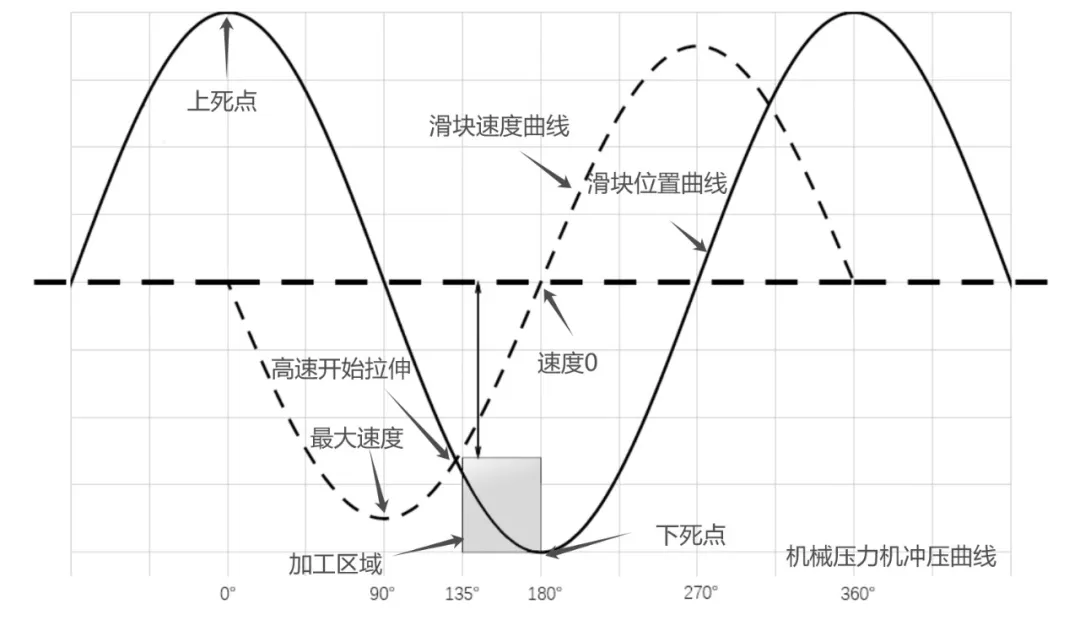

Mechanical presses punch lines

Servo press stamping curve (drawing + holding)

03.High energy saving, green and low carbon

Servo press compared with pneumatic mechanical press, the power saving is about 30%. The mechanical press drives the fast rotation of the flywheel through the continuous load operation of the AC motor, so as to ensure the up and down operation of the slider, so the energy consumption of the mechanical press has two major characteristics: (1) High energy consumption, the motor is always loaded; Energy consumption is uninterrupted, as long as the device is not shut down, even if it is in standby state, it still consumes power.

The servo press has the characteristics of energy saving, mainly because: ① the energy consumption of the motor is determined by the size of the load, the greater the force required to cut off or form the plate, the greater the resistance, the greater the servo motor output torque value, the numerical control system gives the target position and speed value, the resistance encountered on the way, the motor will output to overcome the resistance, maintain the speed, until reaching the target position; ② Servo press built-in energy management system, when the servo motor deceleration or reversal will produce electrical energy, electrical energy stored in the energy module of the press, the servo press force to do work will first consume the energy module of the power, not enough later in the power grid.

Yawei shares servo press typical case

Yawei Shares have many application cases, used in different industries, such as:

01.Silent blanking of medium and thick plates

Sample name

Car lower arm ball seat: BZ/END piece

Material material

forging

Material thickness

8mm

Drawing requirement

Stamping blanking 3 φ8mm round holes, bright belt up to 4mm

Customer pain point

Loud stamping noise; The section is poor, the bright belt is small; The cost of imported punching needles from Japan is high, and the punching needles are scrapped after 10,000 stamping by the crankshaft punch.

Solution

The use of Yawei SKE1-200 tons servo press, precision blanking mode, slow stamping process, empty stroke fast running, so that the noise from the original 98.3dB reduced to 71dB, to achieve silent blanking; The section bright belt is increased from the original 1mm to 5mm; The impact speed of waste material is slowed down by 8 times to achieve non-inductive stamping; The frequency of injection needle use has been increased from 10,000 to 80,000 times.

02.Sheet drawing

Sample name

Micromotor housing

Material material

DX53D-Z material thickness 0.5mm drawing requires a tensile height of 30.5mm

Customer pain point

Sheet drawing, pneumatic mechanical punch tensile cracking; The second step drawing accuracy of the hydraulic press is poor, and the efficiency of the hydraulic press is low.

Solution

With Yawei SKE1-80 servo press, tensile/pulse mode can be used to get good products, servo press speed mode can increase DX53D-Z steel tensile limit by 25%, using shock mode can increase DX53D-Z steel ultimate tensile ratio from 1.9 to 2.85, By planning the motion curve of servo press and optimizing the running speed at different stages of tensile deformation, an efficient servo variable speed tensile curve optimized for tensile forming process was obtained.

As shown in the figure, by using the shock mode of the servo press, the tendency of the tensile sheet to break is greatly reduced; The DX53D-Z steel was stretched by the servo pulse stretching mode. The stress relaxation effect produced by the intermittent action can stretch the part with flange (stress concentration) to 30.5mm, while the ordinary press directly pulls apart. The influence of tension mode and pulse mode on the tensile formability of the piece was studied by SKE1-80 servo press. It was found that the yield of the piece was increased by 7% by the shock mode compared with the tensile mode.

03.High strength steel blanking, forming

Sample name

Small shell material material S60C spring steel

Material thickness

The 2.0 mm

Drawing requirement

The forming height is 20.0mm, and the flatness of the bottom surface is less than 0.03mm

Customer pain point

It is necessary to develop an additional set of shaping molds and allocate an employee to make up, and the finished product rate is still < 80%

Solution

The use of Yawei SKE1-110 tons servo press, the use of multiple forging mode, only change the motion mode of the press, no need to modify the mold structure, no need to press the upper die, without increasing the cost of the mold can significantly improve the accuracy of the top surface, to achieve the flatness of the top surface from the ordinary forming of 0.1mm to 0.03mm.

Arabian Transformers Co. (ATC) has been rooted in Dammam, Saudi Arabia for 25 years and is an important enterprise engaged in power transformer manufacturing in the Gulf region. Adhering to the philos

Recently, BEPO, a benchmark enterprise in Brazil's auto parts industry, officially confirmed the cooperation and purchased two sets of Yawei YLRW-6070 robot laser welding systems, aiming to compre

[Conference Video] On March 26, 2025, YAWEI’s Global Distributor Conference, themed"Borderless Intelligent Manufacturing for a Win-Win Future” was grandly held at the company headquarter. Forty-f

International Sales Hotline:

International Sales Hotline:

86514-86880517

International Sales Email:

International Sales Email:

sales2@yawei.cc

International Service Hotline:

International Service Hotline:

86514-86519121

International Service Email:

International Service Email:

service2@yawei.cc

Copyright © 2025 Jiangsu Yawei Machine Tool Co., Ltd. 苏ICP备05049318号-1

Hi, l am Yawei, How can l help you?