86514-86880517

2025-01-26 162

Recently, Yawei shares 5250 tons of linear seven-axis continuous punching line successfully delivered to the customer Shenyang Huaxing Machinery Industry Co., LTD. This is the first set of large-scale stamping production line delivered by Yawei Shares, using the first sequence of eight-link transmission, with the industry leading stamping technology, combined with flexible production mode, to help customers improve quality and efficiency.

Shenyang Huaxing was founded in 1984, headquartered in Xinmin City, Liaoning Province, is a collection of machining, stamping, injection molding, welding as one of the automation industrial enterprises. Adhering to the "customer first, sincere to the letter, advancing with The Times, the pursuit of extraordinary" spirit of enterprise, and constantly create new competitive advantages and development momentum, the main service customers are BMW, Mercedes-Benz, GM, Honda, Toyota and other well-known auto oems.

At present, the development of new energy vehicles is changing with each passing day, and the automobile Oems have put forward higher requirements for strengthening cost control, improving production processes, and improving production efficiency. Such pressure is also transmitted to the downstream stamping market, and the original hydraulic press production line or manual stamping line gradually cannot meet the current competitive requirements of the stamping industry. After many investigations, Shenyang Huaxing finally decided to buy the 5250 tons of linear seven-axis continuous stamping line of Yawei shares, which greatly improves the stamping efficiency and meets the production of a wider range of auto parts.

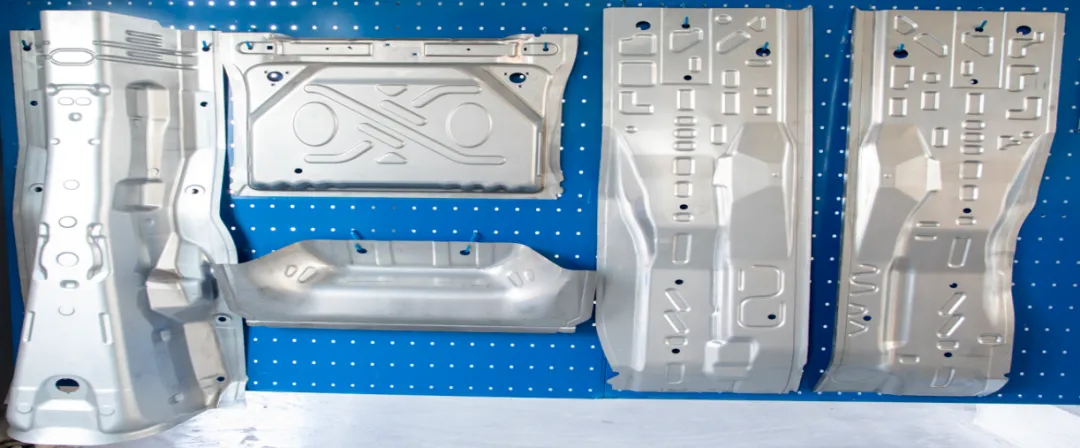

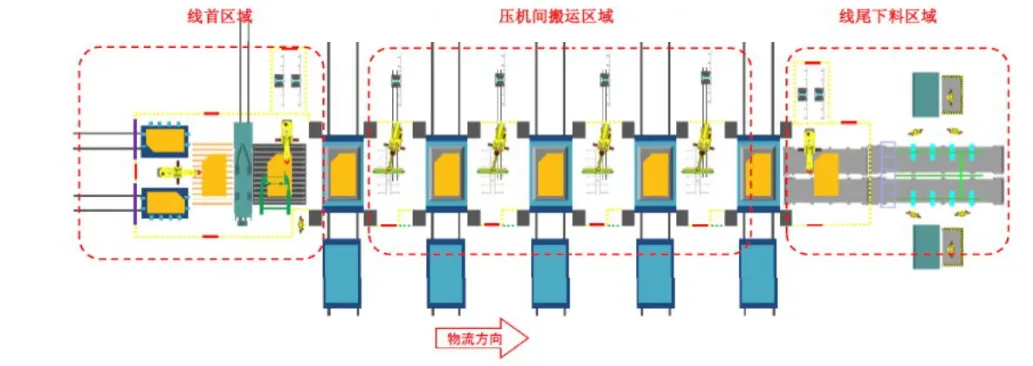

As a production line with high flexibility and high efficiency, linear seven-axis continuous punching line can effectively simplify the robot's handling trajectory by installing a linear seven-axis device on the six-axis robot. The use of industrial robots to achieve plate unpalletizing, stamping workpiece transfer between presses in each process, and the output of the workpiece at the end of the line can not only improve production efficiency, but also save space. Through the coordination of PLC control system, the robot and the press, the loading and unloading robot, the robot and the conveying equipment have accurate and reliable motion coordination relationship. The production line is also equipped with automatic die change and one-click end pickup and other functions, which greatly reduces the time required for the production line to switch the production of different stamping parts, and can be widely used in automotive, white goods and other industries for efficient stamping production, to achieve stretching, punching, shaping, cutting and other functions.

Compared with the traditional intermittent punching line, the linear seven-axis continuous punching line has significant advantages: the continuous production mode, the equipment repeated positioning accuracy is more accurate; Greatly improve production efficiency, beats up to 8-12 times/min; The slider action is consistent and does not stop, which not only reduces the work burden of the clutch brake, improves its service life, but also fully reduces the release of friction heat, and the whole machine is more energy-saving and efficient; The running impact of the slider is small, effectively improving the service life of key transmission components, fully reducing impact noise, and helping to improve the environment of the production site.

Under the background of the current production quality improvement, energy saving and emission reduction in the automobile industry, the linear seven-axis continuous die stamping line has a series of inherent advantages of good process formability, high production efficiency, long equipment life, small movement impact, low energy consumption and noise, and is favored by more and more automobile Ovens and supporting manufacturers. For many years, Yawei shares have been deeply engaged in the field of high-end intelligent equipment and services for metal forming machine tools. As a new force in the business of automatic stamping production line, it has exploded in volume and gradually gained recognition from domestic and foreign enterprises.

We firmly believe that the popularization and promotion of highly flexible, automated and intelligent stamping products will help the further development of automotive and other industries and inject new impetus into the high-quality development of the economy.

Arabian Transformers Co. (ATC) has been rooted in Dammam, Saudi Arabia for 25 years and is an important enterprise engaged in power transformer manufacturing in the Gulf region. Adhering to the philos

Recently, BEPO, a benchmark enterprise in Brazil's auto parts industry, officially confirmed the cooperation and purchased two sets of Yawei YLRW-6070 robot laser welding systems, aiming to compre

[Conference Video] On March 26, 2025, YAWEI’s Global Distributor Conference, themed"Borderless Intelligent Manufacturing for a Win-Win Future” was grandly held at the company headquarter. Forty-f

International Sales Hotline:

International Sales Hotline:

86514-86880517

International Sales Email:

International Sales Email:

sales2@yawei.cc

International Service Hotline:

International Service Hotline:

86514-86519121

International Service Email:

International Service Email:

service2@yawei.cc

Copyright © 2025 Jiangsu Yawei Machine Tool Co., Ltd. 苏ICP备05049318号-1

Hi, l am Yawei, How can l help you?