86514-86880517

2025-03-13 94

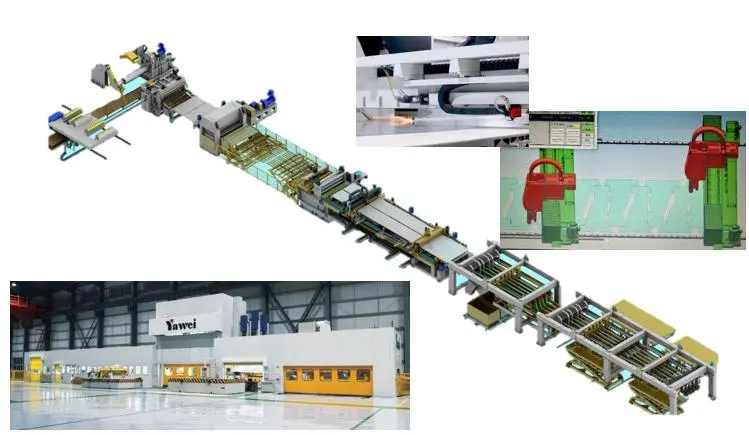

Recently, Yawei Shares successfully signed a high-end steel and aluminum automotive plate laser blanking line project with an internationally renowned automotive group.

1. Project overview

With the development of automotive lightweight technology, new materials, new processes, new technologies continue to innovate and apply, to maximize the realization of automobile energy saving and emission reduction has become an important research topic for major automobile manufacturing enterprises. International high-end car brands have used a lot of lightweight technology, including the application of high-strength steel and aluminum alloy materials.

The most important process of automobile body manufacturing is stamping and blanking. Minimizing material savings and reducing costs associated with molds not only reduces component manufacturing costs, but also reduces energy and carbon dioxide generated during material production. At the same time, the more and more extensive application of laser technology has spawned a variety of new processing processes and equipment changes, and constantly promote the development of automobile manufacturing processes. In view of this, an internationally renowned automotive enterprise group has fully investigated and communicated with a number of suppliers at home and abroad who have the delivery ability of high-end automotive plate laser blanking line, conducted multiple rounds of detailed comparative analysis from design scheme to actual cutting quality, efficiency, etc., and finally fully recognized the product technology and quality of Yawei, which can meet its current and future development needs. Decided to establish a long-term relationship with Yawei.

The company and the customer jointly focused on the laser blanking process of the automotive plate, conducted a lot of repeated discussions on the quality of the finished product, accuracy, production timing, material utilization rate, reducing processing costs, etc., and jointly created a more flexible and intelligent multi-laser head multi-task synchronous processing laser blanking technology. This advanced die-free processing laser blanking system will provide a new solution for automotive plate processing with faster knives, more flexible sets and lower manufacturing costs, effectively making up for the shortcomings of traditional mechanical blanking in flexible and high-strength plate processing, and can meet the internal and external plate supply of various new vehicle body parts faster.

2. High-end intelligent laser blanking line

The laser blanking production line developed by Yawei Co., LTD with deep brand precipitation and technical strength subends the traditional blanking process, combines continuous coil feeding with advanced laser processing, creates more flexible manufacturing conditions with process innovation, produces more high-quality finished products in a short preparation cycle, integrates smart, intelligent, high speed, high efficiency and energy saving to achieve non-modular production. Avoid the cost of manufacturing, replacing, maintaining and storing molds. Moreover, it has the function of quick typesetting and changing, which saves the process of mold manufacturing, trial and optimization of traditional stamping and blanking. It can process ordinary stamped steel, high-strength steel, aluminum plate and other different materials, which can adapt to complex product profiles, easily adjust the parameters of the sheet, continuously optimize the geometry and accuracy, and can quickly change batches and quickly adapt to changes in automobile production. The high-end steel and aluminum composite laser blanking line provided by Yawei has the following innovation points:

(1) The quality of processed products is good

I. High section quality, no burrs, no micro-cracks.

II. High surface quality: no surface contact, damage; Nonsurface foreign body

III. Higher dimensional accuracy: high repeated positioning accuracy; More optimized sheet profile.

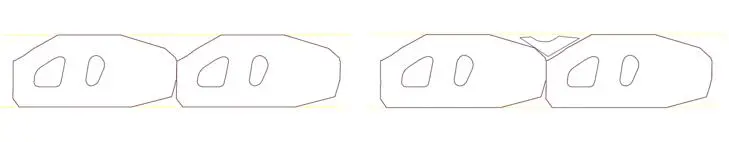

(2) Flexible processing

I. Geometric shape processing: the graphics quickly switch; Quickly set cutting process parameters.

II. Can process a variety of materials: high strength steel, aluminum, stainless steel; Material strength does not affect cutting.

III. Fast cutting of new products and test materials;

IV. No need to transfer between molds, quickly set the production process.

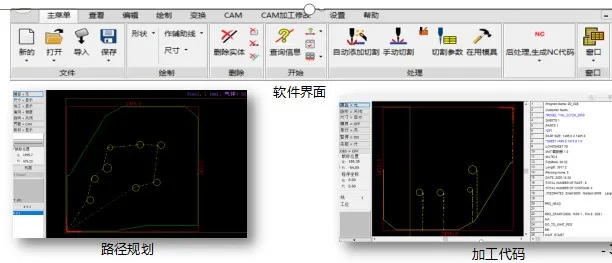

(3) multi-path decomposition, efficient cutting process integration CAM technology, CAM software nesting algorithm optimization based on cutting process characteristics, cutting path optimization, improve cutting efficiency and yield, improve nesting algorithm, make programming intelligent, improve parts switching efficiency and material utilization.

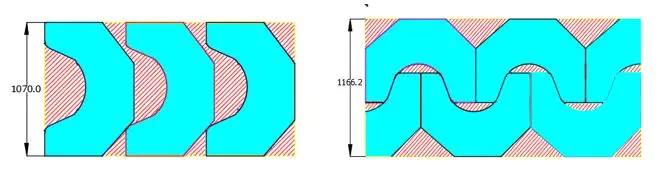

I. Reduce waste by optimizing finished layout: offline programming software automatically generates layout; Reduce the waste generated by the strip

II. Layout recommended roll width: According to the layout width, choose the appropriate roll material of the steel mill standard.

III. Layout is more compact, do not need to consider the limitations of the mold cutting edge, can achieve common edge processing;

IV. Rational material use, layout.

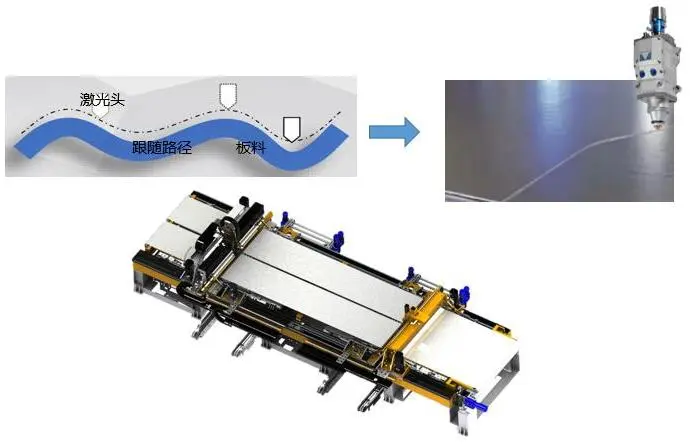

(4) High-grade aluminum alloy outer plate and thin plate ultra-high-speed cutting technology, through the study of high-speed laser cutting control model, continuous improvement of laser cutting process parameters database, to meet the requirements of high-quality automotive outer plate cutting. The high precision motion control theory and method of each motion group are studied by high frequency surge control technology to realize the stability of laser dynamic cutting.

I. More perfect laser cutting process

II. Faster and more reliable dual-head laser path planning

III. High frequency surge control technology to achieve stable follow cutting technology

IV. High suction rate of negative pressure suction stacking system to ensure the surface quality

(5) Automatic product screening, electromagnetic vacuum composite stacker, dry cleaning machine and other new technology application, so that the efficiency, yield has been greatly improved.

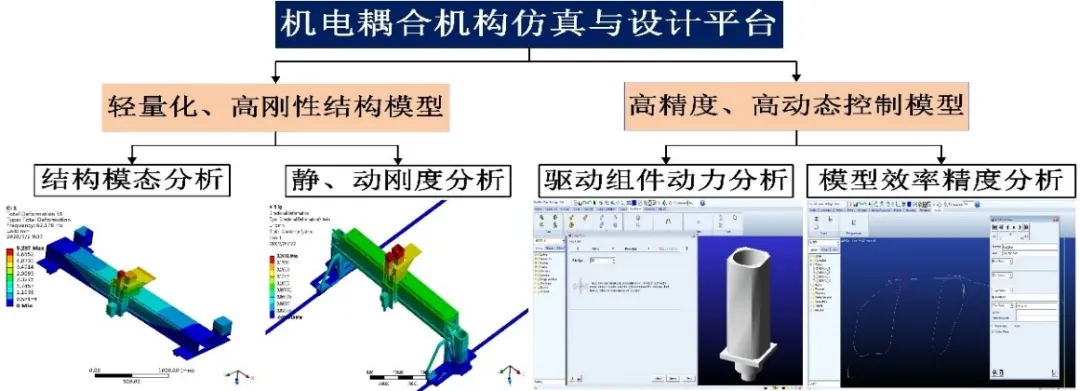

(6) Research on the simulation and design technology of electromechanical coupling high-dynamic cutting mechanism. Through the virtual simulation platform, the mode and dynamic displacement analysis of the macro-dynamic structure of cutting beam and conveying device, as well as the micro-dynamic control research on the high-frequency response of the distance between cutting head and plate, the electromechanical integration of rigid and flexible structure and control system is established, and the coupling modeling and optimization of rigid-flexible control are deeply studied. Meet the requirements of lightweight structure, high rigidity and movement of high speed, high dynamic and high reliability of equipment.

3. Project significance

At present, lightweight is one of the important trends in the future development of automobiles, and the application demand of Oems for lightweight and high-strength materials such as high-strength steel plates and high-strength aluminum plates is increasing. Yawei Shares continue to pay attention to the development trend of the automotive industry, through nearly ten years of continuous innovation, the self-developed high-end laser blanking line can meet the processing of new materials such as high-strength steel and aluminum.

Yawei high-end laser blanking line will strongly promote the innovation of automotive sheet metal processing technology, in the "light manufacturing" era of continuous innovation of laser application process, more processes have been developed, and more application scenarios will be realized. Yawei Shares will continue to listen to customer needs, adhere to lean production management, intensive cultivation of each process, ingenuity to create each product, adhering to the concept of technological innovation, never stop, continue to provide customers with more perfect plate forming solutions!

Arabian Transformers Co. (ATC) has been rooted in Dammam, Saudi Arabia for 25 years and is an important enterprise engaged in power transformer manufacturing in the Gulf region. Adhering to the philos

Recently, BEPO, a benchmark enterprise in Brazil's auto parts industry, officially confirmed the cooperation and purchased two sets of Yawei YLRW-6070 robot laser welding systems, aiming to compre

[Conference Video] On March 26, 2025, YAWEI’s Global Distributor Conference, themed"Borderless Intelligent Manufacturing for a Win-Win Future” was grandly held at the company headquarter. Forty-f

International Sales Hotline:

International Sales Hotline:

86514-86880517

International Sales Email:

International Sales Email:

sales2@yawei.cc

International Service Hotline:

International Service Hotline:

86514-86519121

International Service Email:

International Service Email:

service2@yawei.cc

Copyright © 2025 Jiangsu Yawei Machine Tool Co., Ltd. 苏ICP备05049318号-1

Hi, l am Yawei, How can l help you?