86514-86880517

2025-03-13 100

Xugong Group was founded in 1989. After more than 30 years of development, Xugong Group has always maintained the leading position in China's construction machinery industry. It is a large-scale enterprise group with leading scale, complete product varieties and series, and is highly competitive and influential.

Construction machinery is an important part of equipment industry. Generally speaking, the mechanical equipment necessary for earth and rock construction projects, road construction and maintenance, mobile lifting handling operations and comprehensive mechanized construction projects required by various construction projects are called construction machinery. Construction machinery and equipment are mainly mining machinery, shovel transport machinery, engineering lifting machinery, industrial vehicles, compaction machinery, piling machinery, concrete machinery and other 18 categories of products.

The production of construction machinery is inseparable from the processing and manufacturing of pipes, with the rapid growth of China's pipe production and consumption, pipe processing technology has also developed rapidly, especially the advent of laser pipe cutting machine, but also to pipe processing has brought a qualitative leap. CNC laser pipe cutting machine is a professional equipment for pipe cutting processing, which can achieve high efficiency and high precision cutting of metal round pipe, square pipe, rectangular pipe, Angle steel, channel steel, I-steel and other pipe profiles.

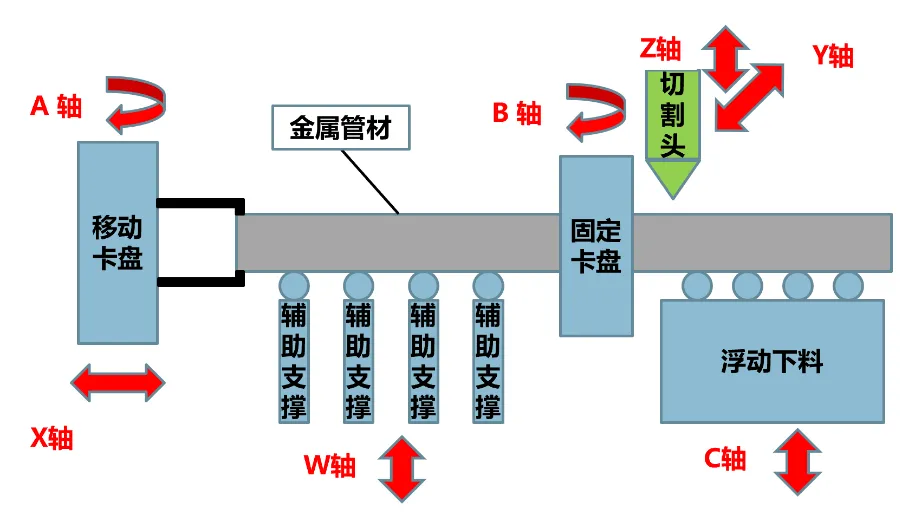

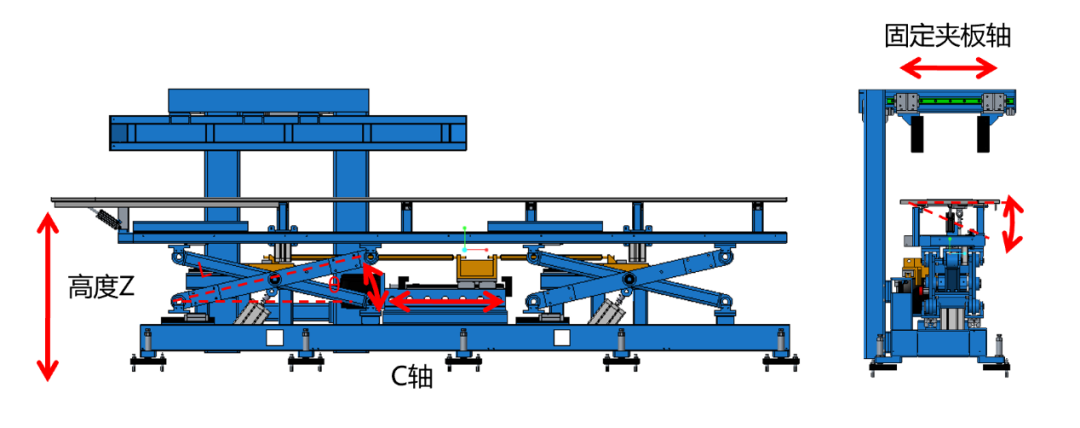

The laser pipe cutting machine uses a moving chuck and a fixed chuck to grip the pipe for rotating motion, and the moving chuck can control the pipe to move before and after (X axis), while the cutting head can move up and down (Z axis) and around (Y axis) relative to the pipe, thus forming a cutting track.

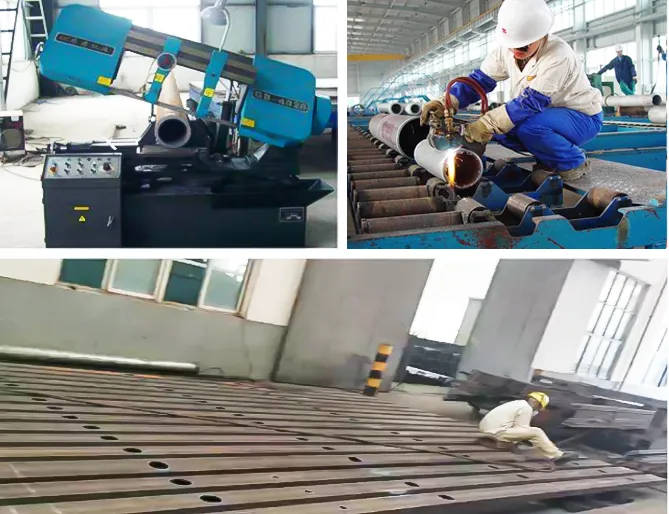

Facing the pipe processing needs of domestic and foreign customers, laser pipe cutting has gradually become their first choice. Sports equipment, construction machinery, agricultural machinery, household, kitchenware and other industries are inseparable from the processing and manufacturing of pipes. Traditional pipe cutting is mainly the use of mechanical cutting methods, such as roller cutting saw, sawing machine cutting, etc. These processing methods are complex, difficult to locate, low processing accuracy, poor quality, and need more manpower.

With the increasing demand for enterprise innovation and transformation, environmental protection standards upgrading and production automation, the customer wants to buy an automated laser pipe cutting machine to replace the original sawing machine at one time, circular saw cutting bevel and drilling machine drilling 3 processes. The main difficulty of this business is: to achieve automation, information collection, feeding, pipe identification, length measurement, automatic call program cutting, weld identification, blanking, palletizing and shipping as one to form a closed loop, and finally realize intelligent pipe processing solutions.

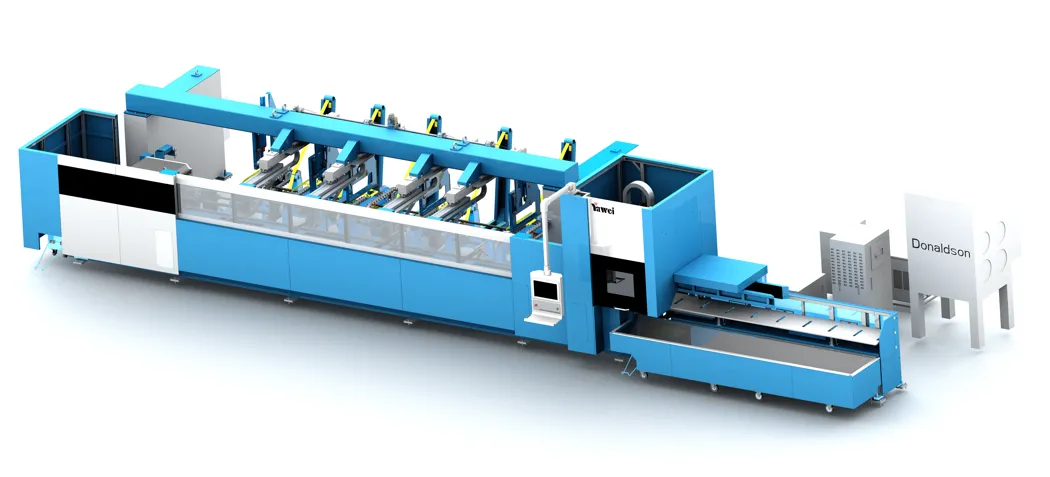

YLT series CNC laser tube cutting machine is a laser tube cutting product that integrates the international cutting-edge laser technology after years of research and development and innovation. The equipment adopts horizontal gantry bed, high-strength, lightweight beam optimized by finite element analysis, high-rigidity precision reducer and complete sets of grinding rack and pinion, Japan THK precision linear guide rail and other efficient transmission mechanism, equipped with IPG fiber laser (photoelectric conversion efficiency ≥40%), integrated by YAWEI NCYT50 system. Faster and more efficient to meet the needs of different industries and customers.

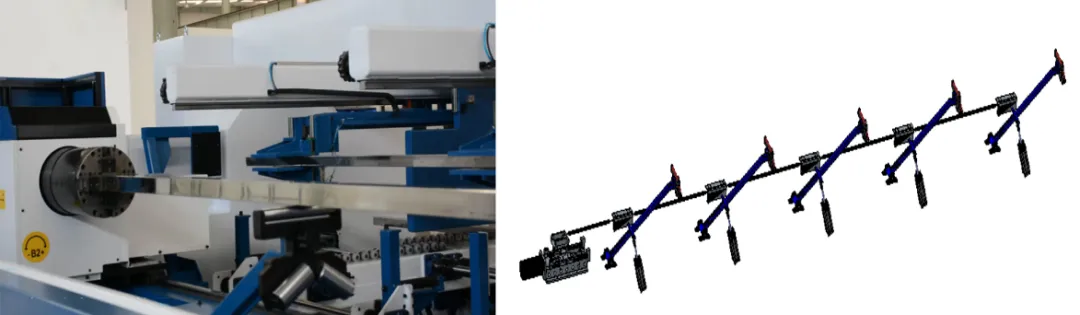

1. Servo dragging device

Auxiliary support is carried out when the pipe is cut to avoid cutting quality problems caused by jitter in the process of long pipe processing rotation;

Single motor drives multiple floating supports synchronous movement through connecting rod mechanism;

2. Intelligent servo feeding system

Servo motor control table height adjustment in real time, to follow the finished workpiece support;

The fixed splint shaft is adjusted according to the pipe section to limit the left and right swing of the finished workpiece;

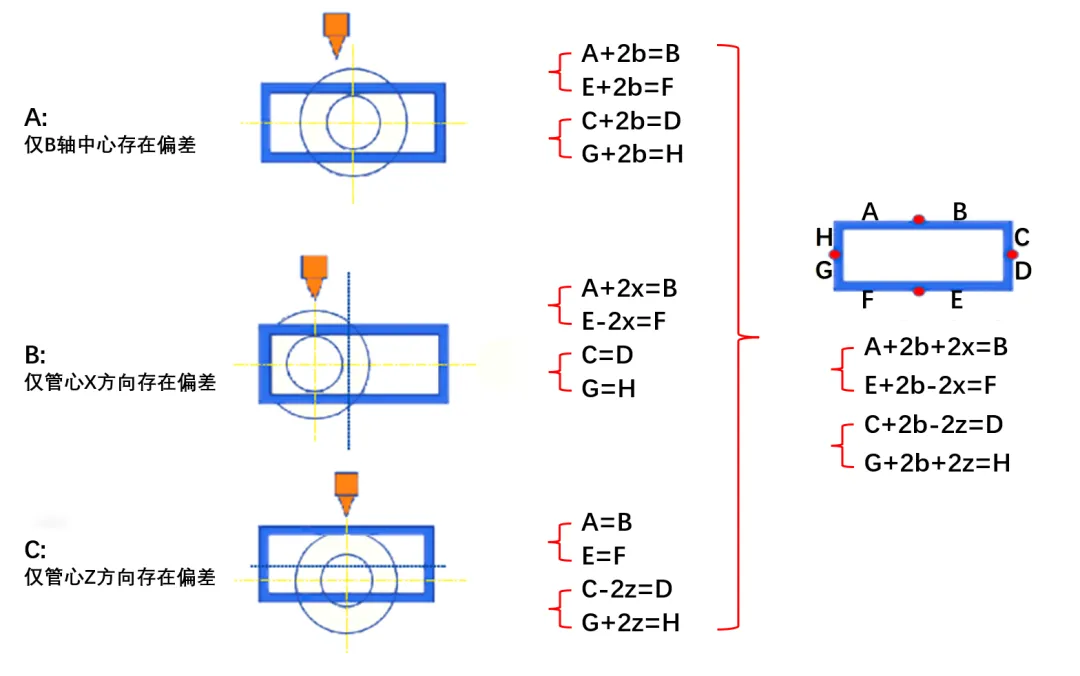

3. Tube precision compensation technology

Pipe bending and distortion compensation function based on the cutting head follow-up sensor. Compared with the auxiliary sensor detection such as the probe, the follow-up sensor has the advantages of high detection efficiency and no loss due to its non-contact detection;

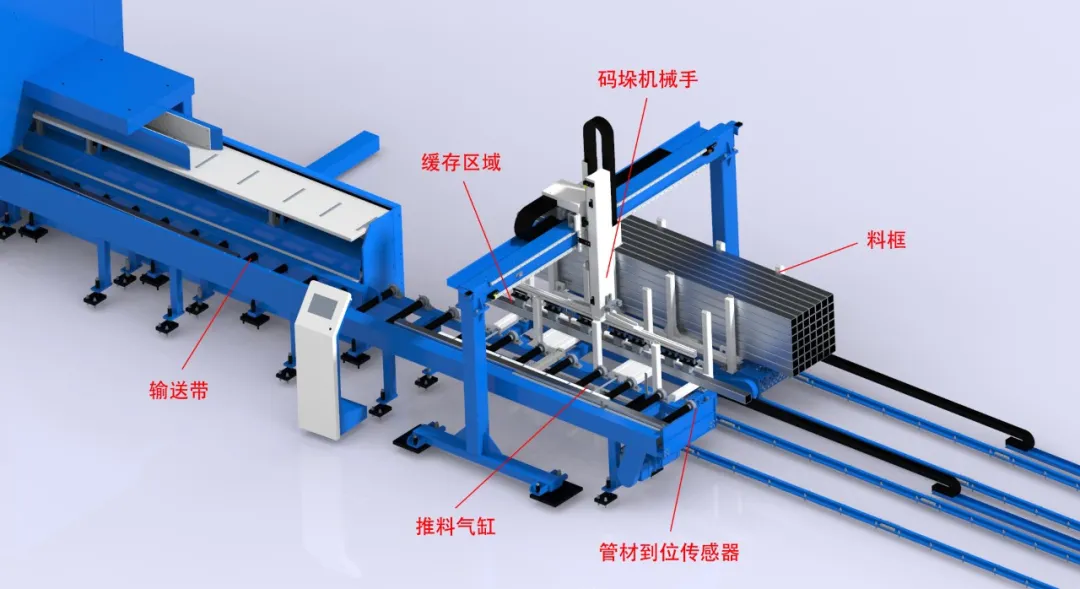

4. FMC automatic feeding system

The feeding device is composed of multiple groups of feeding mechanisms, which can simultaneously carry 1 bundle of pipes to be fed successively, and can realize the needs of small batch and multi-variety production. Through PLC control, the automatic feeding, automatic length measurement, automatic feeding and other processes of the pipe can effectively ensure product quality, and facilitate the operator to grasp the specific data of the pipe to be processed, improve production efficiency;

5. Material palletizing system

The cut finished pipe slips from the blanking slope to the conveying device;

The conveying device will transport the finished workpiece until the pipe is in place and the sensor detects the signal;

The push cylinder pushes the pipe to the cache area;

The palletizing manipulator sorts and palletizes the finished workpiece.

Advantages of YLT CNC pipe cutting machine:

1. High quality: Before the pipe cutting are used sawing machine sawing mode, each cut part has differences and can not guarantee the quality of the incision, and the need for secondary treatment, and laser pipe cutting machine processing using the same set of chuck system, by software programming to complete the processing design, high section quality, high processing precision;

2. Good flexibility: traditional cutting methods may require multiple processes to complete the processing of pipes, and laser cutting can be programmed with programming software for different processing needs, and all processes are completed on a single device;

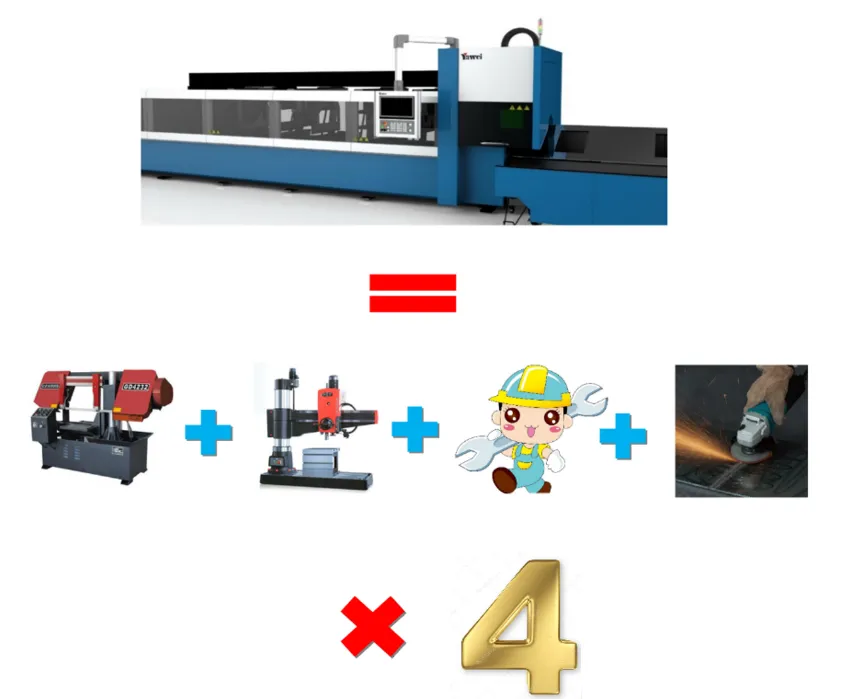

3. High efficiency: The use of laser cutting pipe incision width is generally 0.1 ~ 0.3mm, cutting position and temperature can be accurately controlled, can save 15% ~ 30% of material loss. Automatic bundle loading and intelligent palletizing function greatly improve the processing efficiency, to achieve flexible production, one equipment can be up to 4 sawing machines, cutting efficiency can be increased by 8 to 20 times, processing costs can be reduced by about 60%, greatly saving time and labor costs. At the same time, because of the high quality of laser cutting and less burrs, the time and cost of subsequent processing are greatly reduced.

The traditional sawing machine processing method can not adapt to the current market demand from the aspect of product quality and labor cost, and does not meet its own product positioning. This time, the customer jointly with Yawei Shares to upgrade the production capacity of the metal profile blanking method, further improve product quality, reduce production costs, and create an intelligent production workshop.

In the face of the wave of change in the era of industry 4.0 and the development trend of China's 2025 strategy, Xugong Construction Machinery takes the lead in innovation and innovation, and carries out digital transformation and upgrading around the "14th Five-Year Plan" high-quality development center of manufacturing industry, and at the same time, under the promotion of national policies, construction machinery digitalization and green transformation will promote the industry into a new era.

Arabian Transformers Co. (ATC) has been rooted in Dammam, Saudi Arabia for 25 years and is an important enterprise engaged in power transformer manufacturing in the Gulf region. Adhering to the philos

Recently, BEPO, a benchmark enterprise in Brazil's auto parts industry, officially confirmed the cooperation and purchased two sets of Yawei YLRW-6070 robot laser welding systems, aiming to compre

[Conference Video] On March 26, 2025, YAWEI’s Global Distributor Conference, themed"Borderless Intelligent Manufacturing for a Win-Win Future” was grandly held at the company headquarter. Forty-f

International Sales Hotline:

International Sales Hotline:

86514-86880517

International Sales Email:

International Sales Email:

sales2@yawei.cc

International Service Hotline:

International Service Hotline:

86514-86519121

International Service Email:

International Service Email:

service2@yawei.cc

Copyright © 2025 Jiangsu Yawei Machine Tool Co., Ltd. 苏ICP备05049318号-1

Hi, l am Yawei, How can l help you?