86514-86880517

2025-03-14 75

1. Business challenges

At present, the market prospect of automobile cold-rolled sheet is broad, which is also the business development direction of many steel mills and steel cutting centers. With the development trend of automobile lightweight, the strength of automobile plate is getting higher and higher, and the surface requirements of the plate are also very high, so the uncoiling shear equipment not only needs to meet the shear of high-strength plate, but also can fully ensure the accuracy, flatness and surface quality of the plate to meet the requirements of the automobile plate. And around the current development trend of intelligent manufacturing, many customers hope that in the future, machines and logistics equipment can be connected with sensors, open up all hardware systems, integrate information, realize production site monitoring, modular production and logistics distribution based on downstream customer EDI data interaction orders, and realize automatic input and exit of raw materials, semi-finished products, and finished products. To build their own smart factory.

2. Solution

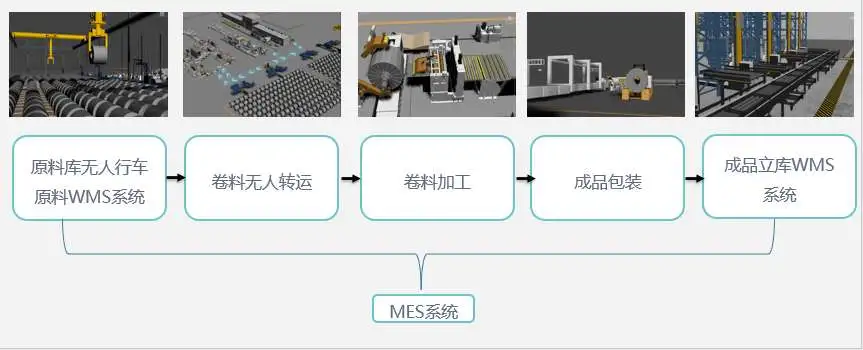

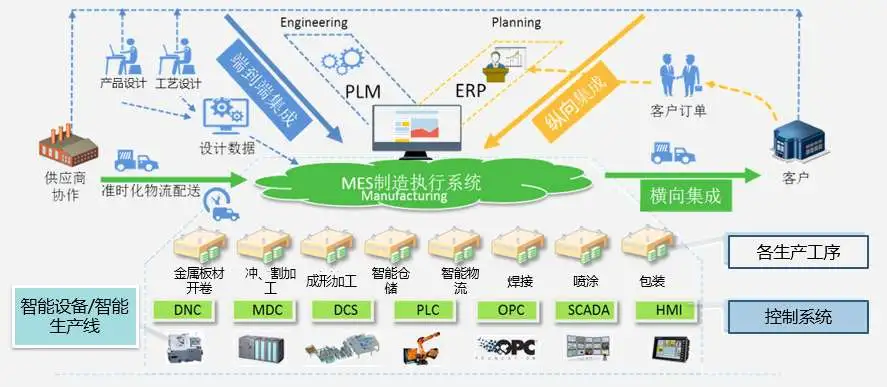

Through the communication with customers, from the market, technology, concept of multiple perspectives, to help customers establish a relatively perfect steel cutting processing system, so as to meet 90% of the cold plate supply market. At the same time, our technicians work with customers to plan the overall layout of the production plant, providing a complete set of solutions from raw material storage, transportation, processing, packaging and warehousing. And the production line all reserved L1 digital interface, on this basis, the future can be for customers to import MES, WMS, APS and other core factory intelligent management software, to help customers achieve information transformation and upgrading.

3. Customer revenue

The processing and manufacturing process of Yawei uncoiling wire equipment ensures the stability of the long-term operation of the equipment in the future, and customers can put more energy on their own product development and market development, and the energy spent on the equipment can be greatly reduced. In addition, we have also reserved L1 interfaces for customers, which can help customers build an exclusive intelligent manufacturing plant in the future, realize real-time collection and remote monitoring of the operating data and status of the production line, inherit big data mining and analysis technology, establish equipment fault diagnosis model, and realize remote fault diagnosis and early warning of equipment.

Focusing on the strategic development direction of "intelligent manufacturing", we provide customers with humanized and customized personalized services, and create an integrated solution and ecosystem of "hardware + software + cloud + integration + consulting planning" to make manufacturing smarter and customers more carefree.

Arabian Transformers Co. (ATC) has been rooted in Dammam, Saudi Arabia for 25 years and is an important enterprise engaged in power transformer manufacturing in the Gulf region. Adhering to the philos

Recently, BEPO, a benchmark enterprise in Brazil's auto parts industry, officially confirmed the cooperation and purchased two sets of Yawei YLRW-6070 robot laser welding systems, aiming to compre

[Conference Video] On March 26, 2025, YAWEI’s Global Distributor Conference, themed"Borderless Intelligent Manufacturing for a Win-Win Future” was grandly held at the company headquarter. Forty-f

International Sales Hotline:

International Sales Hotline:

86514-86880517

International Sales Email:

International Sales Email:

sales2@yawei.cc

International Service Hotline:

International Service Hotline:

86514-86519121

International Service Email:

International Service Email:

service2@yawei.cc

Copyright © 2025 Jiangsu Yawei Machine Tool Co., Ltd. 苏ICP备05049318号-1

Hi, l am Yawei, How can l help you?