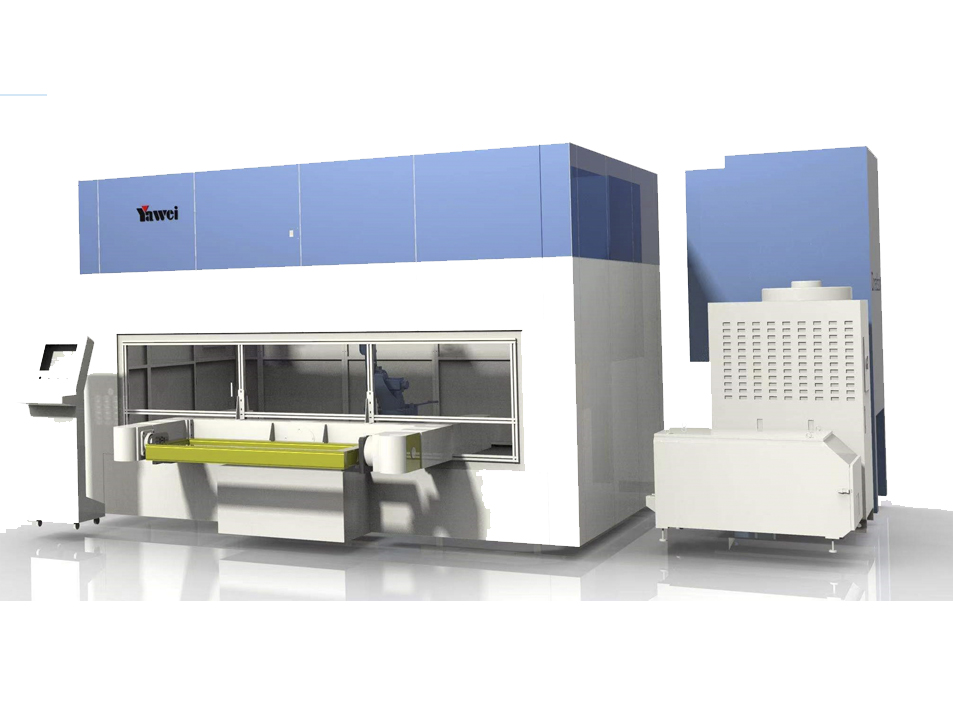

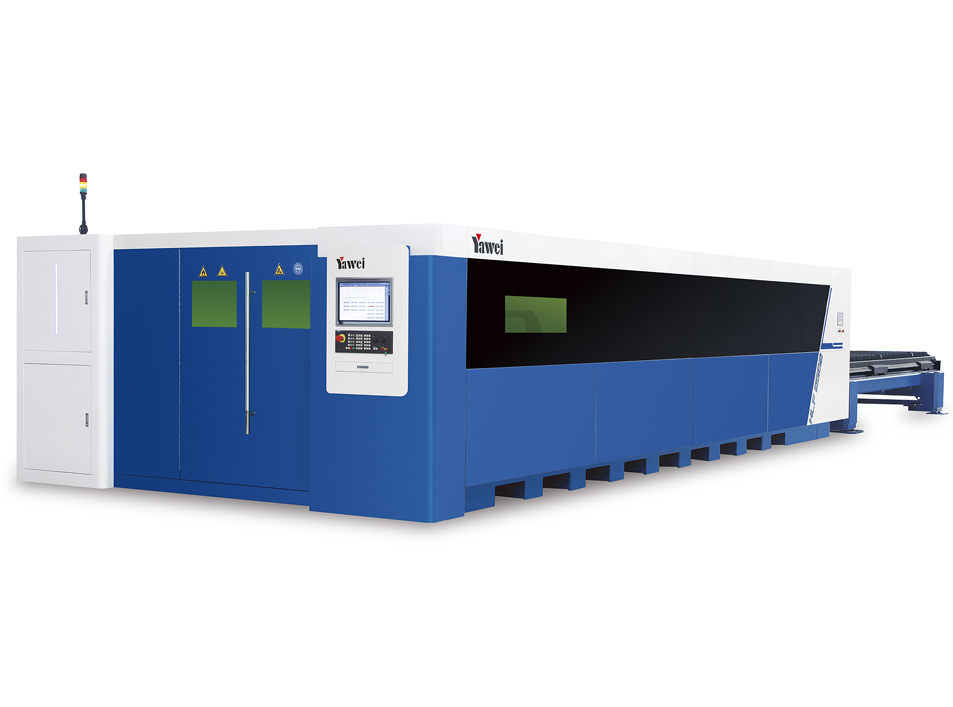

In the face of the wave of change in the industry 4.0 era and the development trend of China's 2025 strategy, XCMG Construction Machinery took the lead in renewing the past, and Yawei assisted XCMG in its transformation and upgrading: using a fully automatic pipe sorting and processing center, intelligent loading, sorting and unloading; automatic The functions of batch loading and automatic unloading and palletizing greatly reduce the number of operators while improving processing efficiency and realizing flexible production.

View Introduction

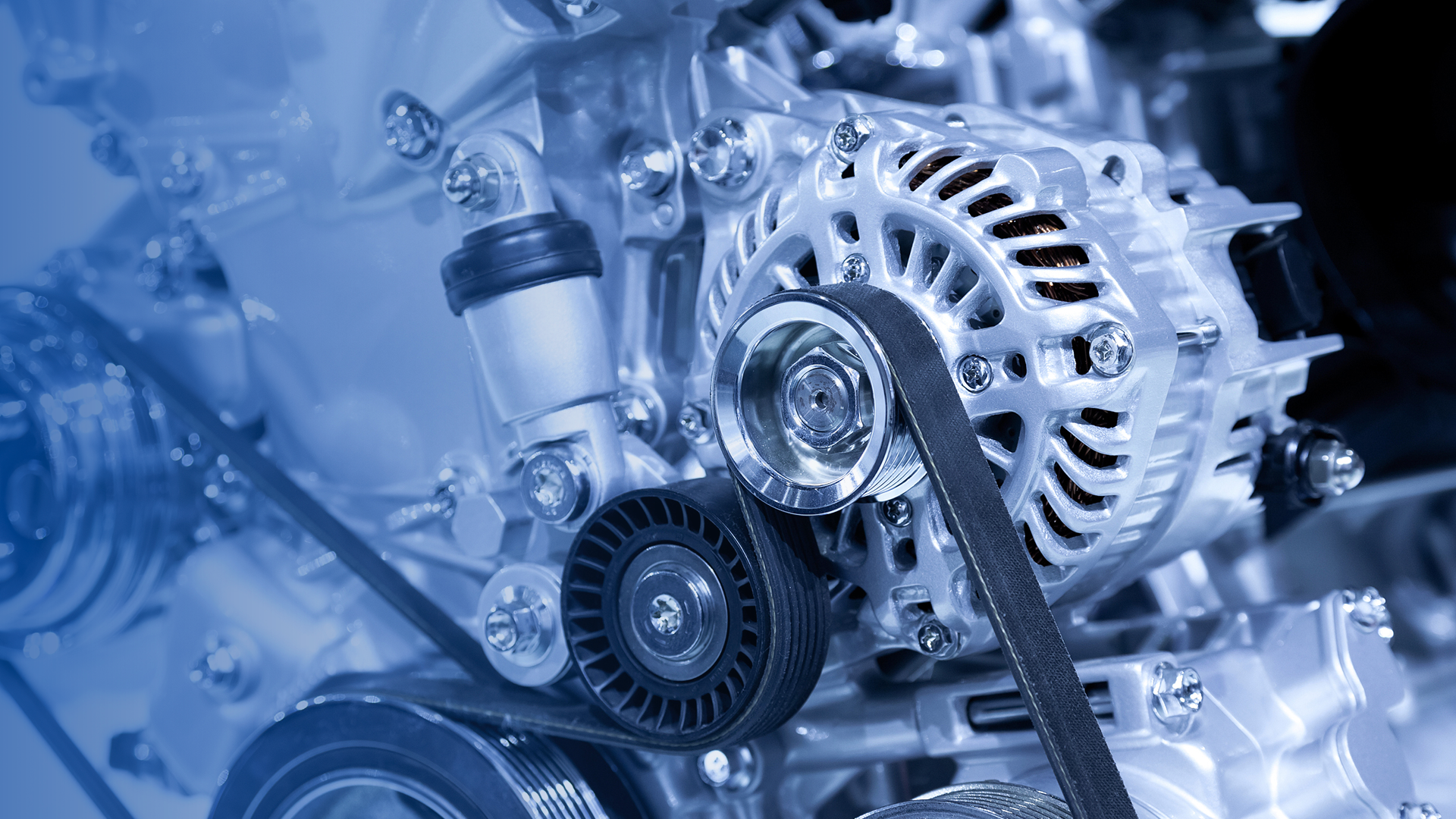

SOLUTIONS FOR CONSTRUCTION MACHINERY INDUSTRY

Construction machinery is an important part of the equipment industry.With the rapid growth of pipe production and consumption in my country, pipe processing technology has also developed rapidly, especially the advent of laser pipe cutting machines, which has brought an unprecedented qualitative leap to pipe processing.CNC laser pipe cutting machine is a professional equipment for pipe cutting and processing, which can cut metal round pipes, square pipes, rectangular pipes, angle steel, channel steel, I-beam and other cross-section pipes with high efficiency and high precision.

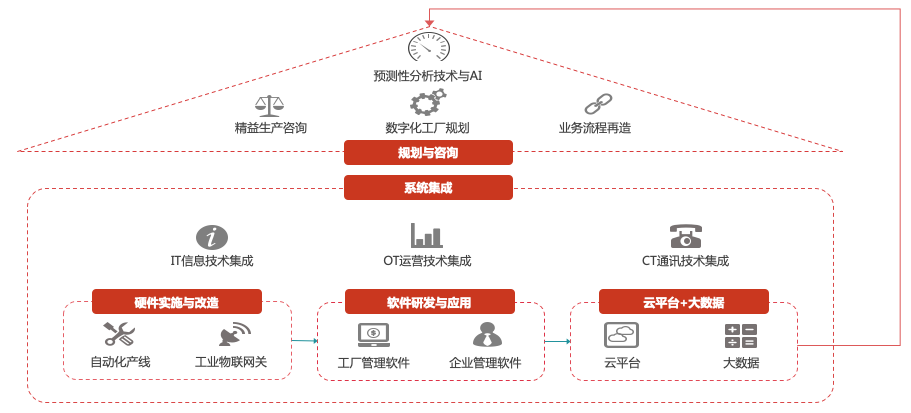

The enterprise has a strong historical deposit, but generally adopts the traditional ant-style operation mode. Most personnel rely on experience to do things, lack of scientific working methods, lack of training, a large number of working methods and experience have not been precipitated and standardized, and personnel have not been effectively utilized. , the hidden labor cost is high.There are many kinds of parts, and the processing cycle of different parts is different. The process is complex. From the beginning of the first process to the completion of the last process, it usually takes several days or even weeks, which has a great impact on the production cycle of the whole machine. The actual production cycle of mechanical finished products is often calculated in months or even years.The status of the production site is not easy to control, the plan is not clear, and the process route is uncertain.

- Staff utilization

- Standardization

- On-time delivery rate

- Production management

Solution

Recommended machine model