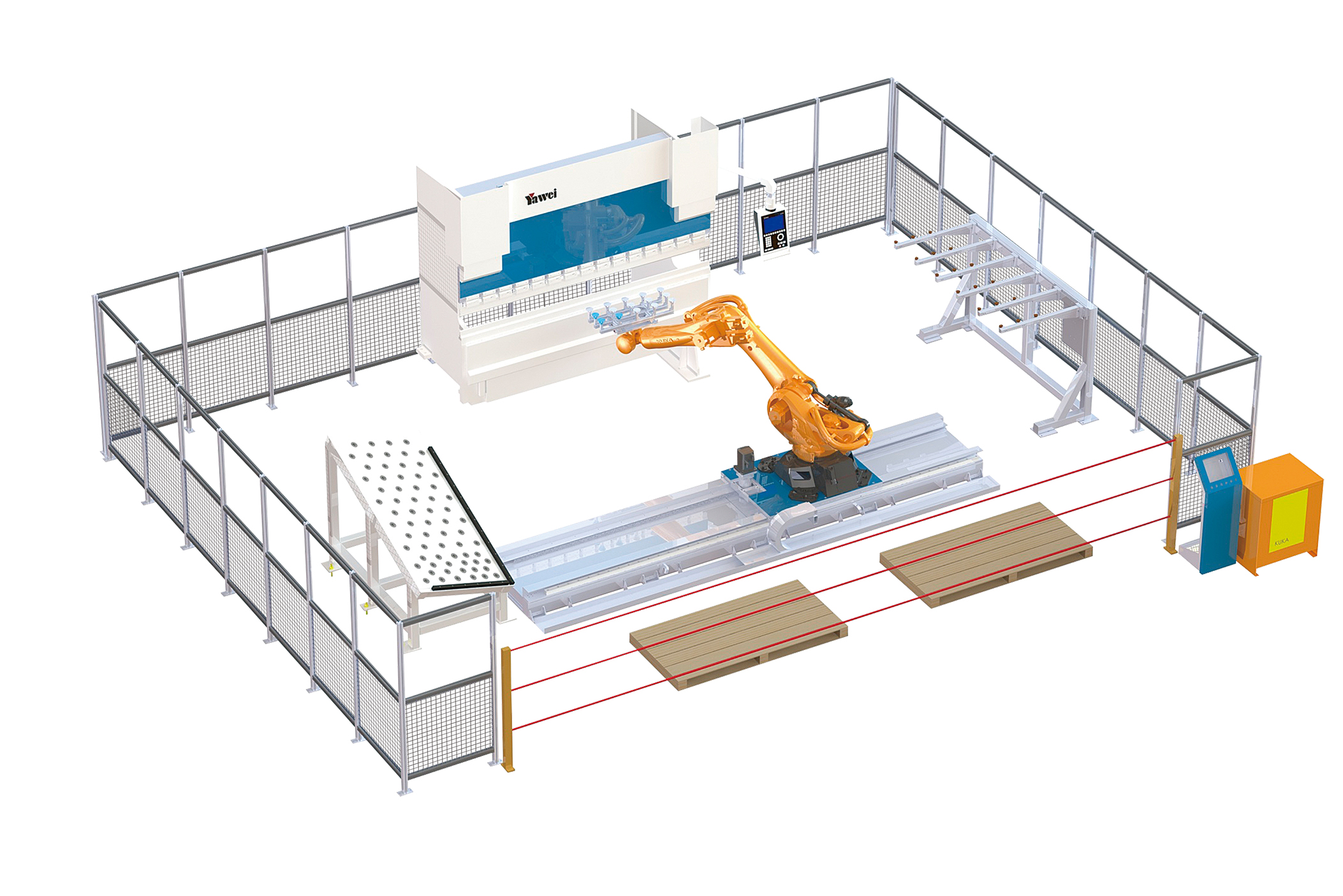

The processing batch of sheet metal parts of the cabinet body is large, and the labor intensity is high, which restricts the increase of the production capacity of the complete set of switchgear. Yawei is the first to launch the automatic sheet metal processing equipment in the industry--switch according to the technological characteristics of the sheet metal parts of the cabinet body. The cabinet flexible processing production line adopts the streamline production of automatic feeding, punching and shearing, bending and stacking, which replaces the traditional single-machine operation mode in different areas. The processing efficiency of a complete set of sheet metal parts is increased by more than 40%. The qualification rate of finished products of robots and parts is also better guaranteed.

View Introduction

Solution for Electric Switchgear Industry

In recent years, the demand for electrical switchgear has remained high due to increased investments in national infrastructure, steady growth in the real estate sector, and the renovation of old power grids. However, the industry has relatively low entry barriers, leading to intense market competition. Therefore, improving production efficiency has become a critical challenge for customers in order to stay competitive in the market.

In the electrical switchgear industry, the processing of cabinet sheet metal components has become a critical concern for many manufacturers. In traditional sheet metal processing workshops, several significant issues often trouble company managers: Chaotic workshop scenes with raw materials and semi-finished products scattered everywhere, causing inefficient workpiece logistics. Difficulty in ensuring equipment uptime, as production orders require a high level of planning and management expertise. Often, upstream and downstream processes do not align, significantly reducing equipment utilization rates. High dependence on sheet metal technical staff, with long training periods for skilled technicians. Recruitment challenges are becoming increasingly apparent in sheet metal workshops. Complex workshop management, with difficulties in predicting order delivery cycles. For orders involving multiple product varieties in small quantities, workshop management costs are high, and delivery challenges are frequent, requiring constant coordination by management to resolve on-site issues.

- Product Quality

- Production Efficiency

- Industry Barriers

- Labor Intensity

Solution

Recommended machine model