The increasing material strength presents a challenge to equipment processing capabilities. High costs are associated with mold development cycles and storage. Material utilization rates are low. There is a trend towards lightweighting in the automotive industry, requiring the processing of new materials such as aluminum.

View Introduction

Solutions for Automotive Industry

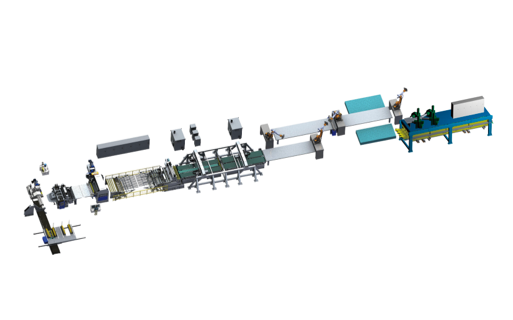

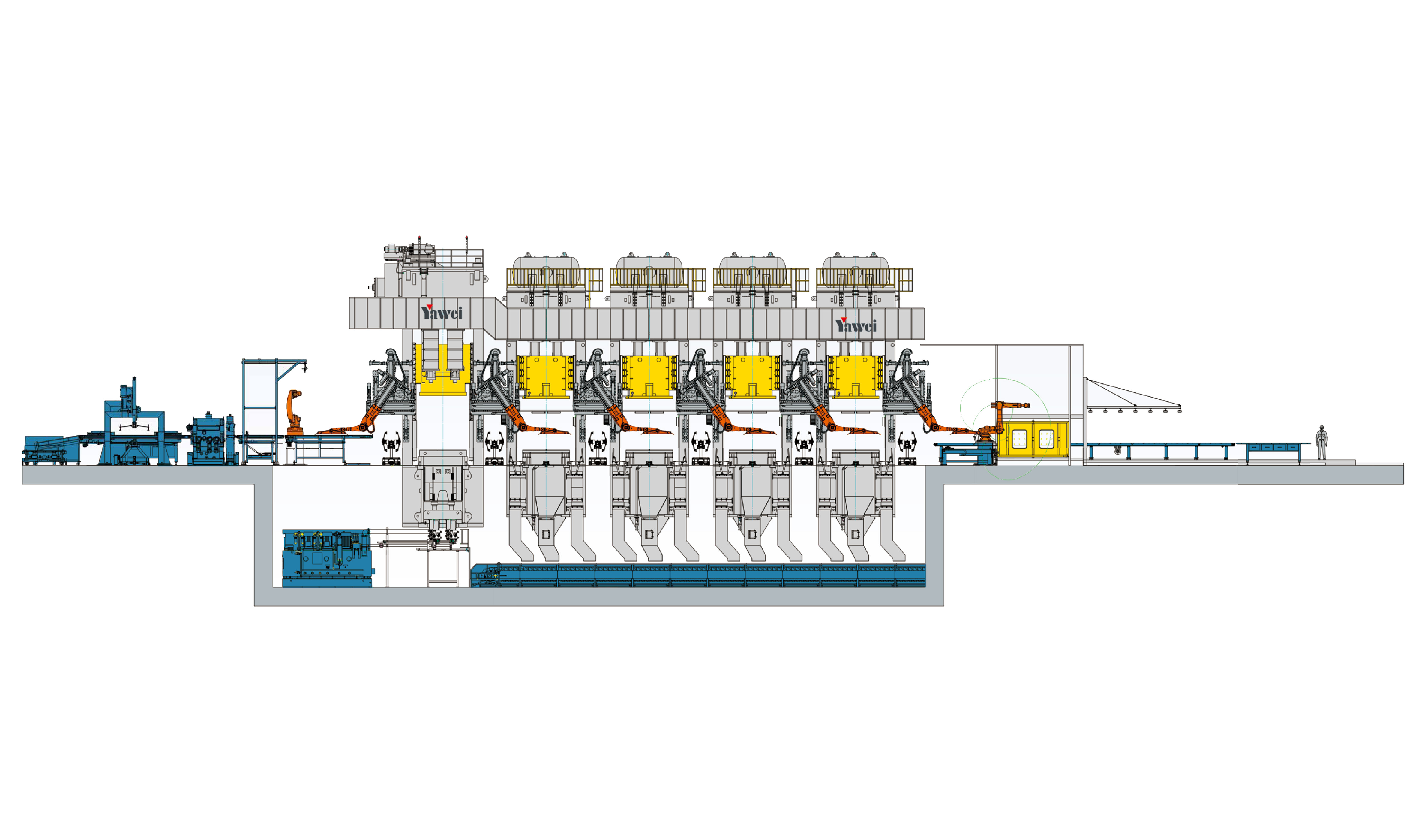

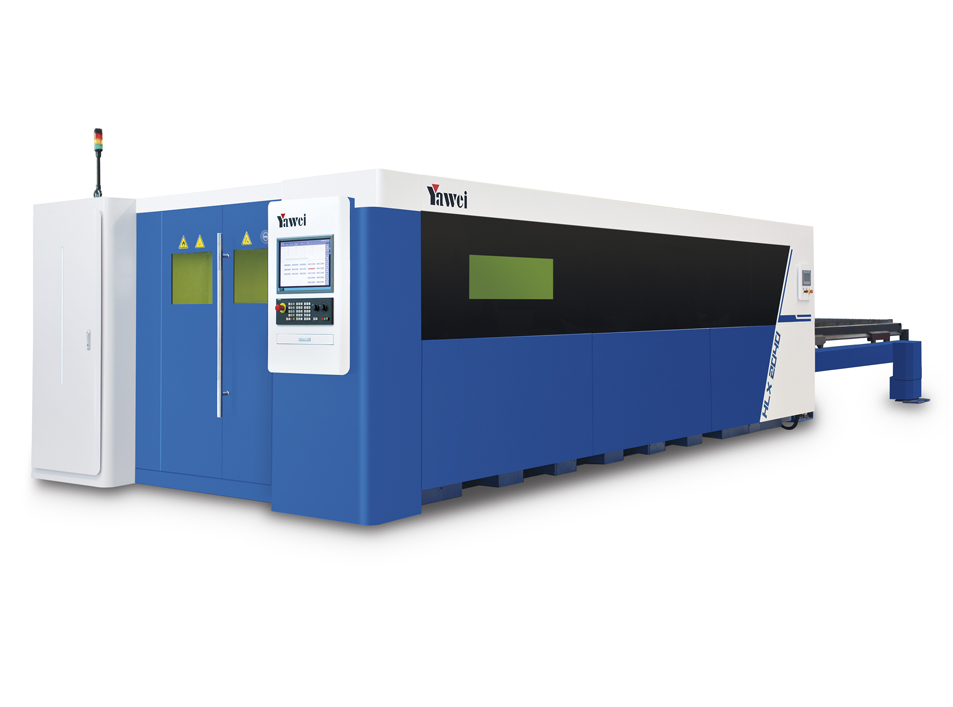

Yawei is committed to providing customized comprehensive solutions for the automotive industry and parts suppliers. Whether it's a cutting line, compact press (progressive die/multi-station press), or stamping line, Yawei can provide cost-effective solutions to help customers gain a competitive edge.

The increasing material strength poses challenges for equipment processing capabilities. The development cycle and storage costs for molds are high, and material utilization rates are low. Additionally, the automotive industry is moving towards lightweighting, which involves processing new materials such as aluminum.

- Material Strength

- Development cycle

- Material utilization rate

- Lightweighting

Solution

Recommended model