With the rapid development of contemporary human living standards, household air conditioners have already entered thousands of households, providing cooling and warmth. The rapid development of commercial air conditioners in recent years is also noteworthy. According to international standards, air conditioning units with a capacity of 3HP or above are collectively referred to as commercial air conditioners. It has a development history of over a century in the world and has been applied in China for more than 20 years. In recent years, there have been frequent price wars in the field of household air conditioners, with the profits of household air conditioners constantly reaching new lows. The continuous development of demand in the commercial air conditioning market has attracted the attention and continuous investment of many air conditioning industry giants. The commercial air conditioning field has become a new battlefield for major air conditioning brands, whether it is foreign brands such as Daikin, York, Carrier, Mitsubishi, McVeil, or Gree, Midea, Haier, etc Many local brands, such as Ox, are eyeing this huge cake and are vying for every inch of land.

View Introduction

Solutions for Home Appliance Industry

Microwaves, washing machines, air conditioners, refrigerators, and most household appliances have become essential items in modern family life. Traditional production models with high labor costs, low equipment utilization rates, and challenging production process management have become pain points in the industry, driving the urgent need for the establishment of commercial smart sheet metal processing factory projects. Yawei employs an integrated solution in its smart sheet metal factory project to address the persistent issues in the existing production model.

Currently, the wages of operators in the general home appliance industry are gradually increasing with economic development and have become an unavoidable part of their product costs. At the same time, the traditional production model of manual operation of machine tools, the traditional logistics model where warehouses and equipment are connected through manual handling, and the traditional management model with opaque production progress and low equipment utilization rates during the production process have become persistent pain points in production management. If these traditional models are not completely overhauled, companies are likely to lose their competitive edge in the fierce competition within the commercial air conditioning industry.

- Labor costs

- Traditional logistics model

- Low production efficiency

Solution

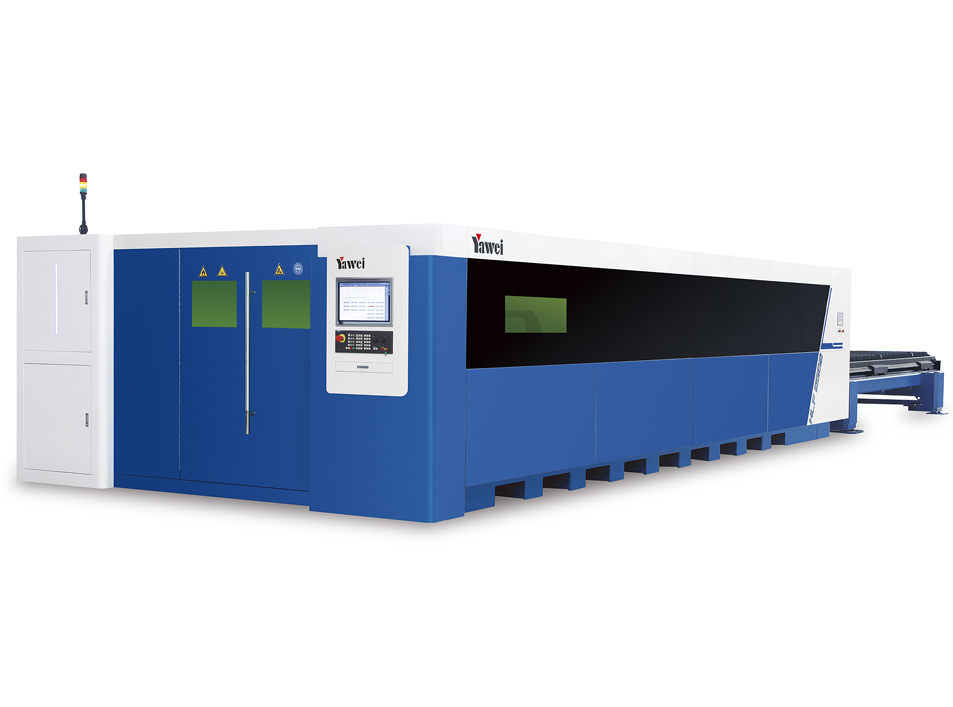

Recommended machine model