"Yawei Corporation Successfully Enters the First Batch of National Upgraded AAA-Level Convergence Management System Standardized Enterprises

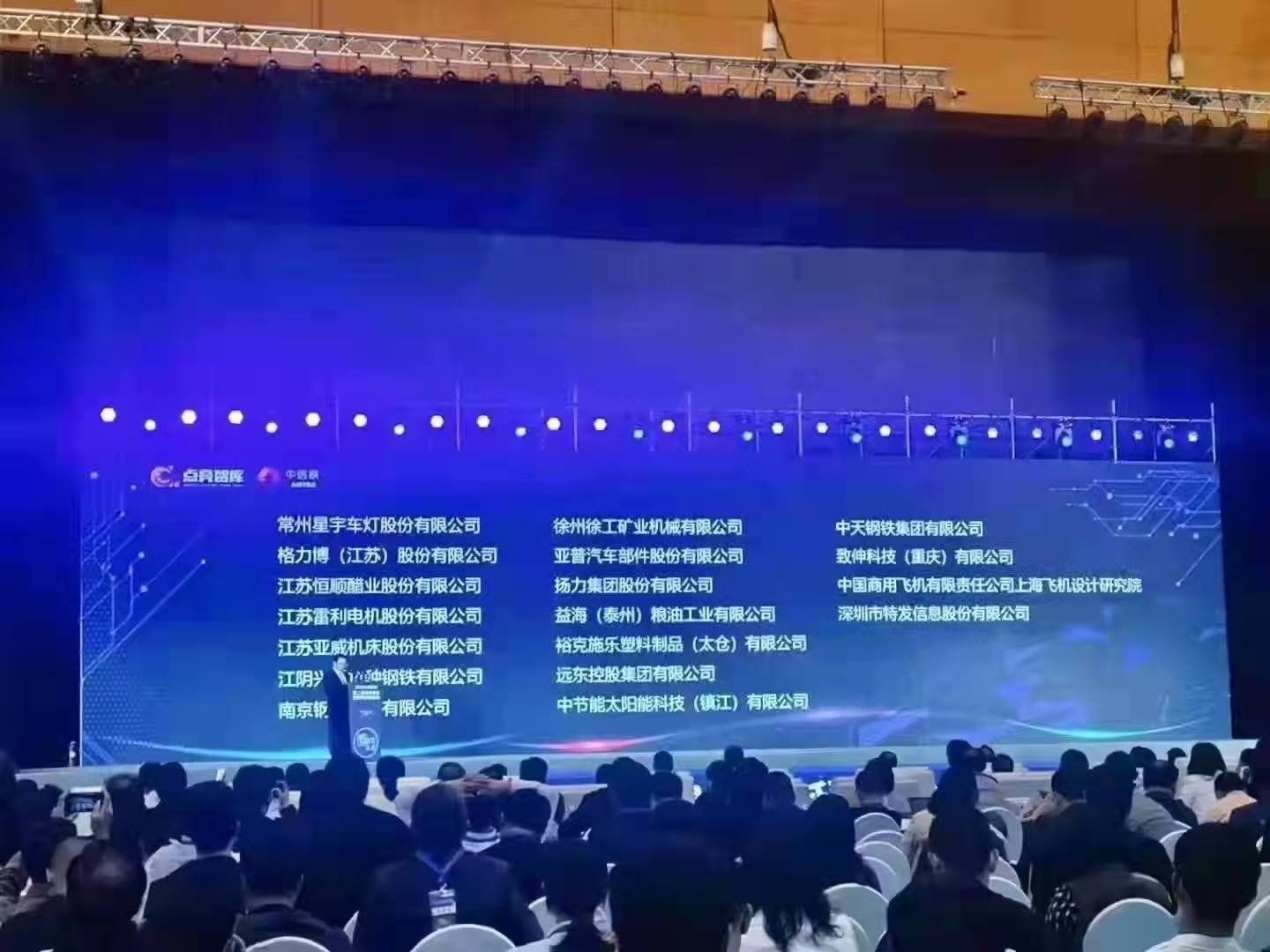

From October 15th to 16th, the Second Industrialization and Informationization Integration and Digital Transformation Conference, co-hosted by the Ministry of Industry and Information Technology, the All-China Federation of Industry and Commerce, and the People's Government of Jiangsu Province, and jointly organized by the National Industrial Information Security Development Research Center, the Industrial and Information Technology Department of Jiangsu Province, and the People's Government of Suzhou, was held in Suzhou. The event released the list of the first batch of enterprises that achieved the upgraded AAA certification for convergence management systems. Yawei Corporation successfully became one of the 18 AAA-certified enterprises nationwide.

Adhering to the principles of 'Strategic Guidance, Integrated Development, Data-Driven, and Intelligent Upgrading' for industrialization and informationization convergence, Yawei Corporation has actively promoted the deep integration of informatization and industrialization for many years. By utilizing core equipment with safety and controllability, advanced applicable process technologies, and advanced informationization and networking methods, integrated innovation has been carried out. The company has established collaborative platforms for design and research, intelligent operational management, intelligent manufacturing execution, and intelligent services. Through methods such as IoT technology and deep integration and application of platform data, the process of deep integration of informatization and industrialization has been continually advanced.

The 'User Demand-Based Product Design and Delivery Service Capability' created this time has successfully achieved AAA-level assessment, with its innovation and demonstration mainly embodied in:

Utilizing a digital collaborative research and development platform to enhance product innovation and process innovation in product research and development. The added value of products has been continuously improved. Digital design and simulation optimization covering the entire product lifecycle have been carried out, gradually promoting the application of 'virtual manufacturing' in technological innovation, reducing product trial production costs, significantly shortening product development cycles, and enhancing parallel, collaborative, and self-optimized research and development design.

Taking the product delivery process as the mainline and achieving overall process control from macro to micro, from overall to detail, and combining macro and micro through planned process monitoring, plan execution, process progress monitoring, and quality information tracking.

Focusing on the upstream and downstream industries of the machine tool industry and using the complete lifecycle services of machine tools and the digital transformation of enterprises as the focus. Yawei Corporation has established integrated customer service capabilities covering equipment management, maintenance, health prediction, online repairs, online diagnostics, spare parts malls, service tracking, and other aspects, maximizing value creation for customers, improving customer satisfaction and loyalty.

Using customer experience to drive design optimization, forming an iterative cycle of research and development design, production and manufacturing, and customer service. Sustaining a competitive cooperative advantage through continuous iteration.

The company's integration of industrialization and informatization activities cover customer-specific demands, personalized product design, flexible product manufacturing, delivery, and the entire service lifecycle. This achieves horizontal and vertical integration of product design, delivery, and service. It realizes integrated design and manufacturing, process control, and production coordination, enabling rapid responses to market and customer needs, and timely completion of product design and delivery services. This has transformed the existing manufacturing model, greatly enhanced intelligent control over the company's manufacturing processes, improved manufacturing efficiency and product quality, reduced product manufacturing costs, and heightened the ability to rapidly respond to increasingly diverse market demands. This effectively safeguards and supports the achievement of the company's goals in the 14th Five-Year Plan."