Solutions for Curtain Wall Industry

Metal curtain walls, as a type of wall decoration used in large buildings, are increasingly favored in the construction industry due to their excellent strength, versatile processing capabilities, and safety features. Among them, aluminum curtain walls are the most widely used. They are lightweight, effectively reducing the building's load, possess excellent rigidity, and provide high flatness, making them a favorable choice for high-rise buildings.

Common aluminum sheet cutting processes include CNC shearing machines, punches, and engraving machines. However, these methods have limitations, such as rough edges, and are prone to cracking during bending. Engraving machines cannot handle special shapes like sharp corners and square corners, while punches are inefficient for cutting irregular plates. China's rapid economic development has led to a significant increase in demand for metal curtain walls in projects such as urban construction, airports, high-speed rail stations, and subway stations. Many metal building material processors are upgrading their technology and expanding their operations. To gain a competitive edge, reduce manufacturing lead times, and improve product quality, they are simultaneously considering high-efficiency, high-quality, and automated laser cutting technology during their technological upgrades.

- Cutting speed

- Operating speed

- Acceleration

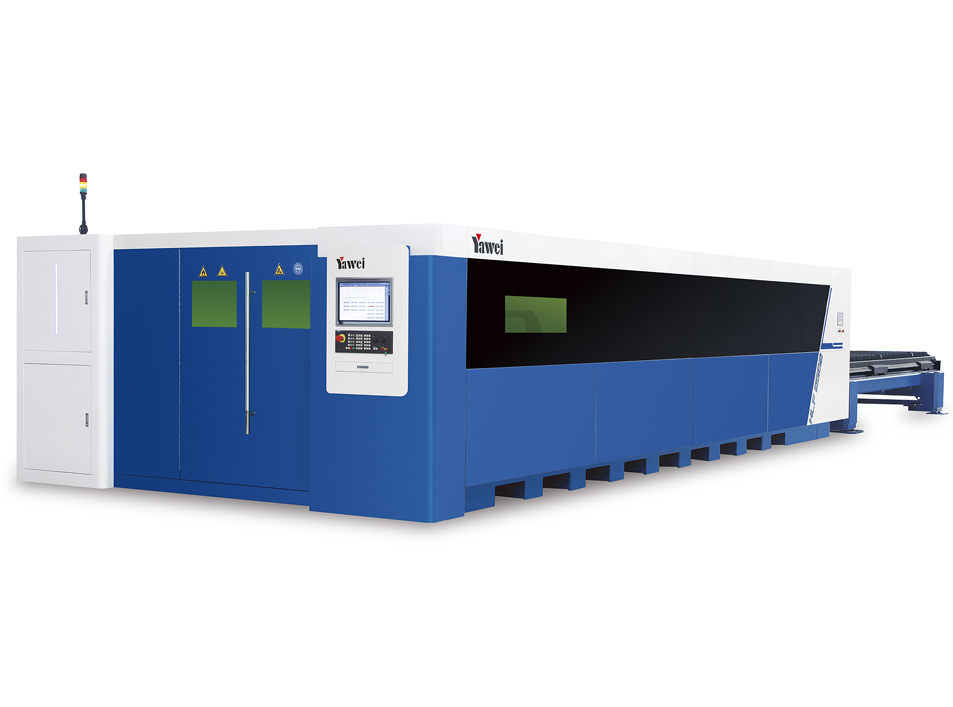

Solution

Recommended Machine model