"Orders Increase and Production is Busy: Yawei Excels in the Test of the Pandemic

In the first half of 2020, under the shadow of the COVID-19 pandemic, the development of manufacturing companies faced numerous unfavorable factors: logistics and personnel mobility were restricted, greatly impacting business operations; the global economy was shaken, and the international pandemic worsened, making overseas market expansion challenging; industry competition intensified, leading to fierce battles in some product markets...

Amid this severe test, Yawei Corporation adhered to its smart manufacturing upgrade strategy, concentrating its efforts on exploring and integrating new competitive advantages. The Yawei team actively pursued orders and ensured deliveries, racing against the clock on various fronts. The sales team overcame difficulties, actively maintained contact and communication with customers through phone calls, online channels, and other means during the outbreak, stabilizing orders. After the situation stabilized, they immediately went to the frontlines to expand the market. The production team worked overtime and tirelessly to ensure that high-quality products were delivered to customers as quickly as possible. With joint efforts, Yawei performed well in the pandemic test, achieving an upward trend in orders in the first half of the year.

Order Rush: Growth in New and Existing Businesses

In March, Yawei Corporation officially signed a 40 million yuan contract with a leading domestic electric appliance company for a smart sheet metal factory project. The project includes equipment such as compound punching-shearing units, laser automation production lines, four-edge bending centers, intelligent multi-column warehouses, and the Yawei Intelligent MES system. It involves the automation, informationization, and intelligence upgrade and transformation of the customer's existing sheet metal factory production model, further promoting the transformation of the customer's sheet metal processing production mode.

This project is a reflection of the company's achievements in 'fighting the pandemic.' In recent years, the company has actively responded to and actively integrated into the strategy of building a strong manufacturing country, proactively adjusting industrial layout and upgrading product intelligence. Affected by the pandemic, downstream companies fully recognized the importance of smart manufacturing, leading to a significant increase in orders for the company's integrated solutions for automation, flexibility, and intelligence.

At the same time, the company's other product businesses continued to maintain strong growth momentum. In the first half of the year, orders for the three major business sectors—metal forming machine tools, laser processing equipment, and intelligent manufacturing services—all achieved year-on-year growth. CNC bending machines maintained strong growth momentum on the basis of already being at the forefront of the global annual sales ranking; industrial robots actively seized external orders, solidifying and expanding market share in industries such as automobiles and ships, and achieving breakthrough orders in fields such as construction machinery and aerospace.

Ensuring Delivery: Working Overtime Together

'Can we finish this today?'

'It should be possible to get the motor running...'

'Customers are pushing quite urgently now, and there are quite a few orders. Let's speed up!'

In the laser and automation assembly workshops, the team leader closely monitored the production progress of orders for laser processing equipment. 'At present, the orders for laser processing are basically scheduled until September. Lately, the employees have voluntarily worked overtime and, under the organization of the company, jointly ensured the smooth completion of production tasks. For the past two months, we only had one day off for the Dragon Boat Festival.'

Not only in lasers but also in all workshops, it has been a busy scene since production resumed. Especially since the second quarter, the peak of the pandemic, combined with delayed deliveries and a surge in new orders, the production department faced unprecedented pressure. The majority of cadres and staff united and rose to the challenge, focusing on production and operational goals. They arranged and organized carefully, balancing epidemic prevention and production, implementing measures such as strengthening production plan organization and management, enhancing logistics distribution, enforcing team labor discipline, and improving equipment efficiency through enhanced maintenance. Despite the challenges posed by the reduced number of personnel due to the pandemic, they managed to achieve a continuous increase in production targets, resulting in a significant increase in employee income compared to the same period last year.

'Not only has our income increased, but the workshop environment has also been upgraded. We feel more motivated when working!' exclaimed a senior employee. Since the second half of 2019, in conjunction with the adjustment of production layout, the company has upgraded and renovated the floors of the workshops, covering an area of 47,200 square meters. Workshops have been equipped with cooling systems, completely rejuvenating the production environment and significantly enhancing comfort. This provides a solid foundation for improving employee production efficiency.

Intelligence: Saving Time and Effort to Increase Efficiency

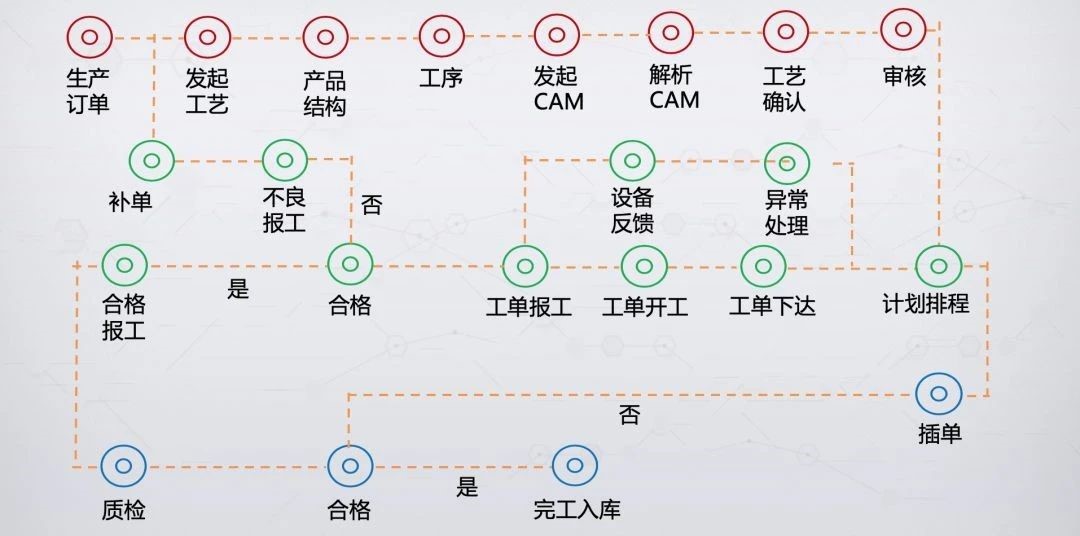

On May 28th, Yawei Corporation's application project for the Ministry of Industry and Information Technology's new model for intelligent manufacturing, 'Application of the New Model of Intelligent Manufacturing for Key Functional Parts of High-end CNC Metal Forming Machine Tools,' held its acceptance meeting. The project's achievements were unanimously recognized by the attending experts, marking a new stage in the construction of the company's intelligent factory. The project has a total investment of 140 million yuan. It focuses on the deep integration of the manufacturing process of key functional parts of high-end CNC metal forming machine tools with digital and intelligent manufacturing environments. It constructs 11 intelligent manufacturing units or production lines closely related to products, including structural component welding, efficient intelligent CNC machining, and intelligent assembly. This improves product quality consistency and overall manufacturing capabilities, promoting the industry's full-chain upgrade driven by data and artificial intelligence.

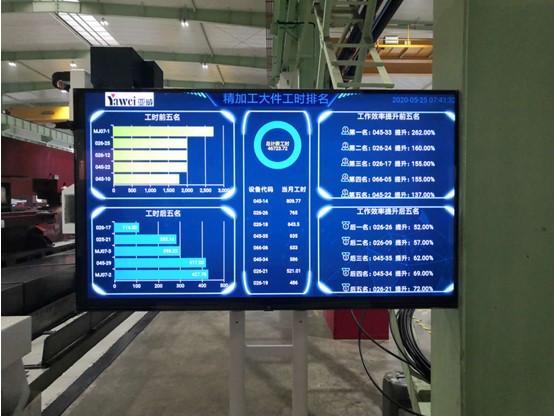

In recent years, the company has comprehensively improved the visualization, automation, and intelligence levels of its machining workshops, propelling lean production to a new level. The effectiveness of this measure is fully reflected in the bustling production scene. In each production workshop, MES, SCADA, and other information systems are put to full use, collecting production information in real-time, analyzing production operation status through big data, exposing and helping improve production problem points in a timely manner, and effectively enhancing production efficiency. In the company's self-designed and constructed intelligent warehousing center, management personnel delved into the application of the information system, working hard and efficiently. In just twelve days, they achieved progress from lagging behind daily material dispensing tasks to exceeding plan schedules.

'The road ahead is long and winding.' Yawei Corporation will continue to strive for excellence, continuously exploring and surpassing itself on the path of intelligent manufacturing upgrades, and reaching new heights in high-quality development!"