86514-86880517

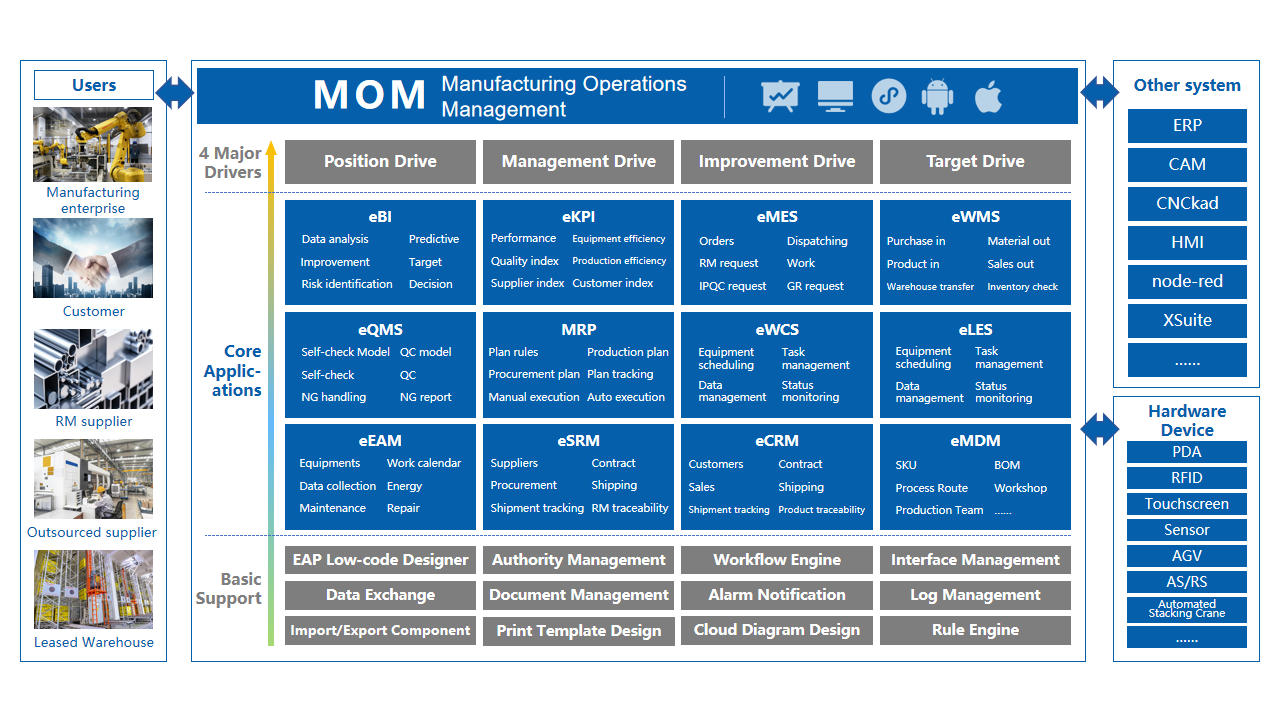

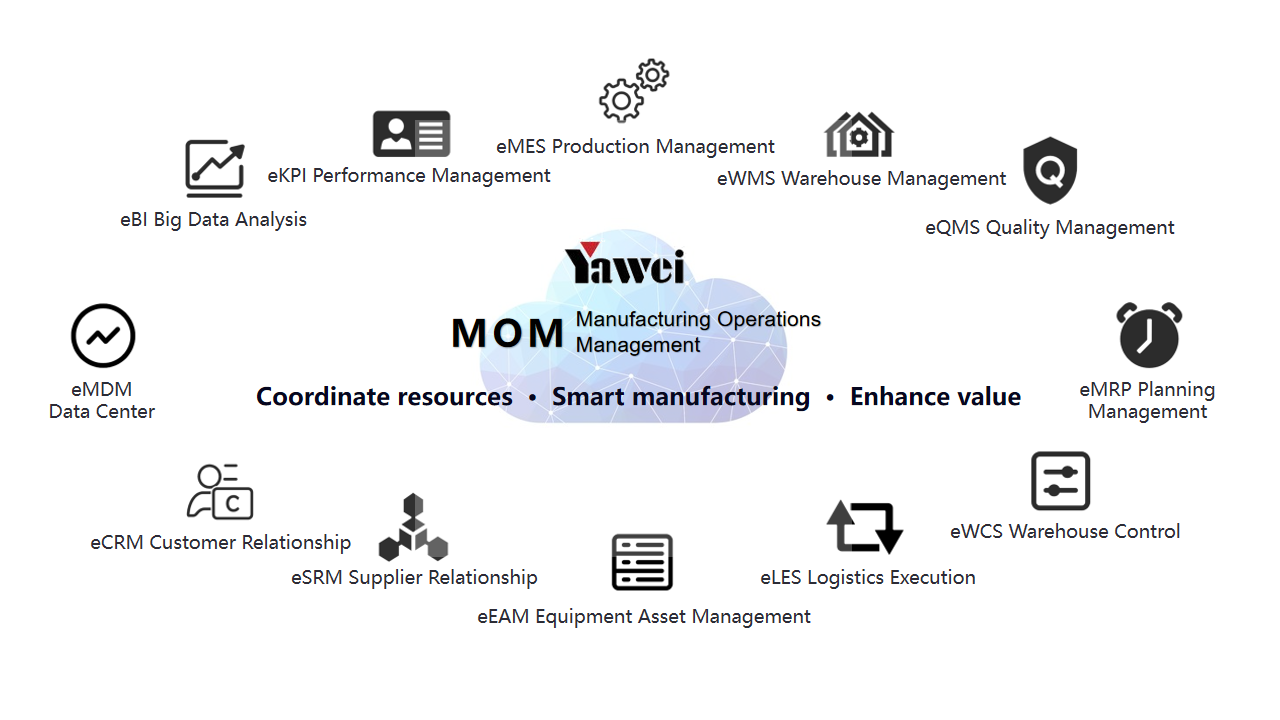

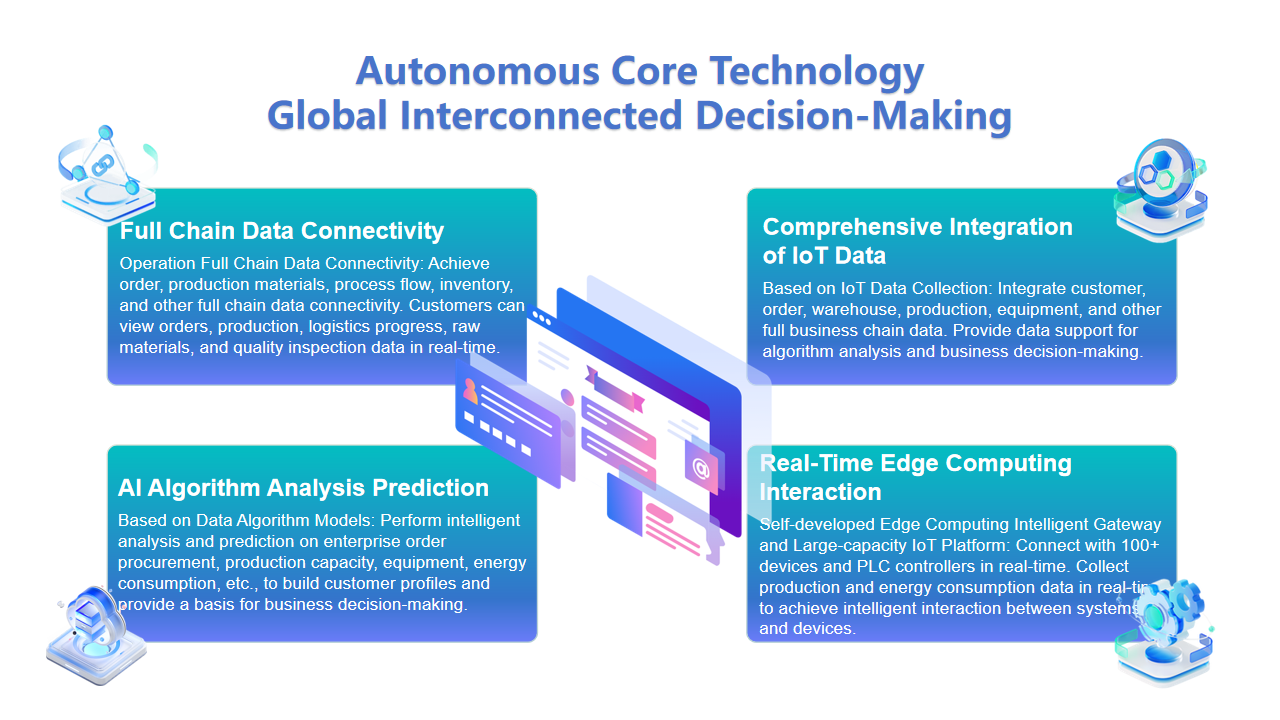

Yawei Intelligent - Manufacturing operation management system MOM is a set of management system for the production and operation management of manufacturing enterprises in the whole industry built by Yawei Intelligent with the help of self-developed EAP low code development platform. As a bridge between the enterprise management system and the bottom workshop executive end, it will efficiently integrate a variety of systems including the bottom equipment and ERP, PLM, to achieve different levels of interconnection and sharing, and provide manufacturing enterprise customers with advanced production scheduling APS, manufacturing execution MES, warehousing management WMS, supply chain management SRM, etc. Twelve core modules, such as quality management QMS and logistics scheduling LES, create a solid, reliable, comprehensive and efficient manufacturing collaborative management platform for enterprises.

Yawei MOM manufacturing operation management system is based on MES manufacturing execution system, joined APS advanced production scheduling, WMS warehouse management, BI big data analysis and other related systems, covering the planning, logistics, production, quality, equipment five manufacturing fields, manufacturing execution and factory operation in one, the implementation of a full range of digital management of the factory software system.

1.eBI Big Data Analysis: provides a professional business intelligence analysis platform to support enterprises to make better strategies and decisions.

2.eKPI performance management: Provide comprehensive and true performance management data of human, machine, material, law and environment to improve the overall operation efficiency of enterprises.

3.eMES production management: Executive level production management system, so that production data, visualization, standardization.

4.eWMS storage management: Optimize the storage process, improve storage efficiency, reduce storage costs, and save storage resources.

5.eQMS quality management: Build a quality system, improve the yield of enterprise products, and achieve quality traceability.

6.eMRP plan management: Guide the development of production and procurement business, run through the entire supply chain, receive sales demand, issue production and procurement, and run through the enterprise's six fields of people, financial, material, supply, production and marketing.

7.eWCS warehouse control: The control system between WMS and PLC system seamlessly connects the two levels of logistics flow business.

8.eLES logistics execution: With material pulling as the core, it realizes a series of intelligent logistics scheduling and control processes such as automatic loading and unloading of workshop equipment and intelligent material scheduling and management.

9.eEAM equipment management: Realize the whole life cycle management of the whole plant equipment.

10.eSRM supply chain management: Connect the upstream and downstream supply chains of enterprises, improve the efficiency of the supply chain as the core, and promote the reform of the overall digital capability of the supply chain.

11.eCRM Customer Management: Realize the management concept of marketing, sales and service automation through information technology, and help enterprises to achieve a customer-centric management model.

12.eMDM data center: standardization of data management for data generation, standardization of information services for data consumption, clarification of management responsibilities for data maintenance, and standardization of service interfaces for data interaction.

1. Support system integration, data sharing, unified management of multi-factory mode, and data integration management across and across borders.

2.B/S system architecture, support secondary development, cross-platform access, not limited to the operating system compatible with a variety of browsers.

3. Meet the requirements of.NET and Java dual engines for different development languages and deployment, the system is stable and can use multiple development languages to build clients, and the factory can expand its business by itself.

4. Support a variety of communication protocol interfaces, can be connected to a variety of intelligent manufacturing field most collection equipment data.

5. Support cloud platform virtualization deployment, while ensuring data security and privacy.

International Sales Hotline:

International Sales Hotline:

86514-86880517

International Sales Email:

International Sales Email:

sales2@yawei.cc

International Service Hotline:

International Service Hotline:

86514-86519121

International Service Email:

International Service Email:

service2@yawei.cc

Copyright © 2025 Jiangsu Yawei Machine Tool Co., Ltd. 苏ICP备05049318号-1

Hi, l am Yawei, How can l help you?